- One-stop service

- Advanced Germany Technology

- Power energy saving in PVC pipe making machine

Primier PVC Pipe Extrusion Machine Factory

| Mixer | Hot and cold mixer |

| Loader | Screw loader |

| Extruder | SJZ conical twin screw extruder |

| Extrusion die | High-quality alloy steel material |

| Vacuum tank | 5.6 meters tank(SS304) |

| Haul-off | rubber claw haul-off |

| Cutter | Non-dust cutter and planetary cutter |

| Belling machine | U and R type mold |

Choose the Right PVC Pipe Extrusion Machine for the PVC pipes you want to produce!

BenK 16-32mm four cavities PVC pipe extrusion machine can produce four pipes in the same time, 16-32mm PVC pipes can be used for electrical wire conduit pipes and home water pipe. BenK adopts Siemens brand PLC and touch screen on PVC pipe extruding machine. The four cavities PVC pipe extrusion line has high speed advantages, it can save clients’ investment to meet large quantities demand. BenK has become one of the large PVC pipe extrusion machine factories in China Now.

- Size: 19m x 2m x 3m

- Whole line power: 90Kw

- Production speed: 8-15m/min

- Pipe Size: 16-32mm with an adjustable wall thickness

BenK 16-63mm double cavities PVC pipe extrusion machine adopts SJSZ65/132 conical twin screw extruder to produce 16-63mm uPVC pipes. it can reach 200-250kg/h. Our PVC pipe extrusion machine using AC saving energy motor, it can help you save electricity in producing PVC pipes. We use double cavities design in 16-63mm PVC pipe production line, it has higher capacity than single cavities. We also use the separated vacuum tank in double pipe PVC pipe extrusion machine which is more easier to operate for your staff.

- Size: 19m x 2m x 3m

- Whole line power: 90Kw

- Production speed: 2-10m/min

- Pipe Size: 16-63mm with an adjustable wall thickness

Benk 50-110mm Double Strand PVC Pipe extrusion machine has higher production speed when compared with single cavities PVC pipe producing machine. We adopt separate design on vacuum tank, invidual driving on haul-off and dust-free technology on cutter. BenK has many experiences on export PVC pipe making machine, and we also can supply factory layout and installation layout to you. It will save your time when PVC pipe machine arrived in your factory. Welcome to send inquiry Now!

- Size: 22m x 2m x 3m

- Whole line power: 140Kw

- Production speed: 3-10m/min

- Pipe Size: 50-110mm with an adjustable wall thickness

Benk 50-160mm double out PVC pipe extrusion machine is similar to 50-110mm double-strand PVC pipe extruding machine, their differences are the size of main extruder, extrusion die, the diameter of vacuum tank. 50-160mm double out PVC pipe production line at least need cm80/156 conical twin screw extruder, it can reach max. 400kg/h. The socketing machine can choose U and R type tools. Any problems on your old machine, welcome to send us your questions!

- Size: 22m x 2m x 3m

- Whole line power: 170Kw

- Production speed: 3-10m/min

- Pipe Size: 50-160mm with an adjustable wall thickness

BenK 20-110mm PVC pipe extrusion machine is consist of two extrusions die, which can produce 20-110mm PVC pipes, it is a single cavity PVC pipe extrusion line, we can use cm55/110 or cm65/132 extruder on the pipe production line. Benk recommed the 20-110mm single out PVC pipe producing machine to you when you lack investment funds, as it can produce big range size to meet market demands. When you earn more money, you can use this line only to produce 50-110mm PVC pipes.

- Size: 19m x 2m x 3m

- Whole line power: 85Kw

- Production speed: 5-15m/min

- Pipe Size: 20,25,32,40,50,63,75,90,110mm with adjustable wall thickness

BenK 50-160mm single out PVC Pipe Extrusion Line is consist of extruder, mould, vacuum tank, haul-off cutter, belling machine. The difference between 50-160mm double out PVC pipe production line are the haul-off and cutter. 50-160mm single out PVC pipe making line adopt three claws haul-off and planetary cutter, but double out PVC pipe use two claws haul-off and chipless cutter. It need two extruding molds, and the planetary cutter can do chamfer function. Welcome to send your inquiry here.

- Size: 22m x 2m x 3m

- Whole line power: 90Kw

- Production speed: 5-10m/min

- Pipe Size: 50,63,75,90,110,125 and 160mm with adjustable wall thickness

50-250mm PVC Pipe Extrusion Machine is similar to 50-160mm PVC pipe extrusion line, it also need two sets extrusion die, which are 50-125mm one set die and 160-250mm one set die. We exported 5sets the same machine to Egypt market. Benk is one of the best PVC extrusion machine manufactrer in Zhangjiagang city, China. If you want to know the price of PVC extruder and other machines, please send an inquiry to us Now!

- Size: 22m x 2m x 3m

- Length of vacuum tank: 6meters

- Production speed: 3-8m/min

- Pipe Size: 50,63,75,90,110,125,160, 200, 250mm with adjustable wall thickness

75-315mm PVC pipe extrusion machine is a single out production line, we use cm80/156 plastic extruder as the main extrusion machine, the capacity can reach 400kg/h. It needs four claws tractor, and we can choose AC motor or Servo motor for each claw of haul-off. Planetary cutter working by big bearing with direct connection which is not working by a small bear with chain. Welcome to send us your demands about PVC pipe extrusion line, we are always can be your reliable supplier!

- Size: 25m x 2m x 3m

- Length of vacuum tank: 6meters

- Production speed: 3-12m/min

- Pipe Size: 75,90,110,125,160, 200, 250,280,315mm with adjustable wall thickness

160-315mm PVC Pipe Extrusion Machine is the same extrusion machine with 75-315mm PVC pipe extruding machine, the difference is the extruding die, all extrusion tools are made as per client’s demands of pipe outer diameter and wall thickness. We use bigger diameters extrusion die which can get higher pressure then make higher quality PVC pipes. 160-315mm PVC pipe producing machine which means produce 6-12inch pipes. Is these sizes you want to invest NOW!

- Size: 25m x 2m x 3m

- Length of vacuum tank: 6meters

- Production speed: 3-12m/min

- Pipe Size: 160, 200, 250,280,315mm with adjustable wall thickness

200-400mm PVC pipe extrusion machine is mainly used to produce 8-16 inch PVC pipes, when we say the pipe size, it always mean for its outer diameters. These PVC pipes can be used for drinking water and water supply, we can produce different pressure level pipes for different application. Do you want to know how to produce different pressure level? For bigger diameter pipes, we need add one set spray cooling tank which can cool down the pipe faster to ensure its round shape. Big size pipe can get bigger profits.

- Size: 31m x 2m x 3m

- Length of vacuum tank: 6meters

- Production speed: 3-8m/min

- Pipe Size: 200, 250,280,315, 355, 400mm with the adjustable wall thickness

315-630mm PVC Pipe Extrusion Machine needs big size cm92/188 extruder, one set 315-630 PVC pipe die head, vacuum calibration tank, spray cooling tank, planetary cutter and belling machine. It can produce 650kg/h. Haul-off use 6claws, each claw is 1.1Kw. The belling machine has two ovens and cooling by the circle water. Ask them to send inquiry and video Now!

- Size: 33m x 2m x 3m

- Length of vacuum tank: 6meters

- Production speed: 3-8m/min

- Pipe Size: 315, 355, 400,450,500,560,630mm with the adjustable wall thickness

500-800mm PVC pipe extrusion machine is the biggest PVC pipe extrusion machines by manufacturers choose, we need 92/188 or two extruders co-extruding together. It needs one set vacuum tank and two sets spray cooling tank. 8claws haul-off can produce 80000N power. 500-800mm PVC pipes are used for big construction for sewage or water supplying systems.

- Size: 38m x 2m x 3m

- Length of vacuum tank: 6meters

- Production speed: 3-8m/min

- Pipe Size:500,560,630,710,800mm with the adjustable wall thickness

Your Premier PVC Pipe Extrusion Machine Manufacturer in China

Benk PVC pipe extrusion machine also named PVC pipe extrusion line which is used to make different size PVC pipes with the different formula. PVC pipe extrusion line is one of the plastic extrusion machine, which including conical twin screw extruder, extrusion die, vacuum tank, tractor and cutter as well as auxiliary machine, stocking machine and crusher. Benk is a professional PVC pipe extrusion machine manufacturer which can supply good quality PVC pipe manufacturing machine with affordable prices in China. Benk not only supply PVC pipe extrusion line, we also can calculate the cost of plant you need after knowing more details for the pipe you need. Then we will design a diagram for our PVC tube machine and draft for the plant layout you need invest after you confirm pipe extrusion line finished, we also can supply the pipe extrusion process video or manual if you need. Before confirming your order with us, please let me know how many percents of calcium you want to add in the formula, then we can order screw and barrel for you accordingly, usually, we will add 50% or 100% calcium compare with PVC in order to save production cost for you. Benk can be you reliable PVC pipe manufacturing machine supplier, as all parts and raw material of our machines are chosen the best from China, we are confident with our machines, would you like to send us your inquiry? Thanks. If you are looking for cheap PVC pipe manufacturing machine or high-quality conduit pipe making machine manufacturer, you are in the right, we supply ODM for PVC pipe machine and plant for you one-stop.

- Data Sheet

- Videos

- Image Gallery

- Special Characters

- Send Enquiry

Different PVC pipe production line for PVC pipe size range

| Model | BKE63 | BKE110 | BKE160 | BKE315 | BKE450 | BKE630 |

| Pipe range | 16-63mm | 32-110 | 75-160 | 110-315 | 200-450 | 315-630 |

| Extruder | SJZ51/105 | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ80/156 | SJZ92/188 |

| Main motor | 18.5KW | 22KW | 37KW | 55KW | 55KW | 110KW |

| Capacity | 100-150 | 150-200 | 20-250 | 350-400 | 350-400 | 700-800 |

1. Benk use top quality conical twin screw and barrel and screw will be designed as per your calcium percent in your formula. 2.Benk adopts easy disassemble footer of vacuum tank which can move tank left and right without hit tank and more easily. 3. All pipe connected with fitting without welding, and we install a filter and water speed value in the middle of water pipes, and the water speed valve is controlled by water temperature, when the temperature of the water is high, water supply will be more which can save more power for you with non-stop production everyday. 4. Benk is also a PVC mixer manufacturer in China, when you buy PVC pipe extrusion line, you must need a high-speed PVC mixing machine.

The Ultimate Guide to PVC Pipe Extrusion Machine

Many customers worry about working with new PVC pipe extrusion machines from China, as they do not know how to find reliable manufacturers or suppliers, and fear about the quality and authenticity of the products and equipment sold. They are also not aware of which type of double screw extruder to choose to manufacture pipes of various sizes. This can become a headache for you if you are not familiar with the machines, or if the machines are not of good quality. To avoid this hassle, Benk Machine has some very important tips for you to help you buy PVC pipe production line from China. We make the full list for the pipe out diameters you want to produce, along with which type of conical twin screw you need.

1 Single out pipe production line:

| Pipe OD(mm) | Extruder | Haul-off | Cutter |

| 50-160 | SJZ65/132 | Three claws | Chip free cutter/planetary cutter |

| 160-250 | SJZ80/156 | Three claws | Planetary cutter |

| 200-400 | SJZ80/156 | Four claws | Planetary cutter |

| 315-630 | SJZ92/188 | Six claws | Planetary cutter |

Single out PVC pipe extrusion machine

2 Double-out PVC pipe making machinery:

| Pipe OD(mm) | Extruder | Haul-off | Cutter |

| 16-63 | SJZ65/132 | Two claws | Dust free cutter |

| 50-110 | SJZ80/132 | Two claws | Dust free cutter |

| 70-160 | SJZ80/132 | Three claws | Chip free cutter/planetary cutter |

PVC dual out pipe making machine

They are many factors which influence the size of the machine in whole PVC pipe extruding line, the primary reason being that customers want to save cost, so they opt for smaller machines in the production line. For questions regarding PVC pipe extrusion machines, please contact our support team anytime. Benk Machinery provides all necessary information for PVC pipe production line, the extrusion process, formulation and operations, and it can help you choose the best PVC pipe extruding machine manufacturer in China. https://youtu.be/JdSTOsrrn6A

Chapter 1: Benk Machinery Produces PVC Pipe Extrusion Machine in China.

China is the biggest industry equipment manufacturing and industry production country in the world. With the improvement of technology in plastic extrusion machines, more and more clients opt to buy PVC pipe extrusion machines from China. However, if you are ready to import PVC pipe extrusion machine (UPVC pipe extrusion machine) from China, you need to consider things like choosing the extruder manufacturer, the plastic extrusion process, how much to invest in the PVC pipe plant, how to operate the machines, how to save costs, and other relative things. So how to solve them by yourself? You need to know the important electric and parts brands which are used in the PVC pipe extruder, machine parts for PVC pipe line, production formula and operation, and so on. Then you can determine how to choose the plastic extruding machine manufacturer in China, how much money you need to invest in machines, land, and other relative costs. Benk Machine is trustworthy plastic extrusion machine manufacturer in China, that provides the top quality PVC pipe machines to reduce troubles for you in production, save more power costs, and solve all problems in machines with the fastest response. Benk machine has served many clients in India, Middle East, Africa, and South-east Asian countries, and they always make machines with top standard and according to requirements from clients. We also have an experienced support team that can solve machine and production formula problems for you in the shortest time possible. If you need any help with the products or machinery, please contact our support team.

China is the biggest industry equipment manufacturing and industry production country in the world. With the improvement of technology in plastic extrusion machines, more and more clients opt to buy PVC pipe extrusion machines from China. However, if you are ready to import PVC pipe extrusion machine (UPVC pipe extrusion machine) from China, you need to consider things like choosing the extruder manufacturer, the plastic extrusion process, how much to invest in the PVC pipe plant, how to operate the machines, how to save costs, and other relative things. So how to solve them by yourself? You need to know the important electric and parts brands which are used in the PVC pipe extruder, machine parts for PVC pipe line, production formula and operation, and so on. Then you can determine how to choose the plastic extruding machine manufacturer in China, how much money you need to invest in machines, land, and other relative costs. Benk Machine is trustworthy plastic extrusion machine manufacturer in China, that provides the top quality PVC pipe machines to reduce troubles for you in production, save more power costs, and solve all problems in machines with the fastest response. Benk machine has served many clients in India, Middle East, Africa, and South-east Asian countries, and they always make machines with top standard and according to requirements from clients. We also have an experienced support team that can solve machine and production formula problems for you in the shortest time possible. If you need any help with the products or machinery, please contact our support team.  Benk Machine brings the following to you as one of the best plastic extruder machine manufacturers in China:

Benk Machine brings the following to you as one of the best plastic extruder machine manufacturers in China:

- Professional experience

- Fast delivery for extrusion machines

- Longtime guarantee for our equipment

- Quick testing and installation for you by our engineers

Apart from this, our team has a solution for all your problems. From suggestions on machines before you order, manufacturing machines, testing extrusion equipments before loading, training your staff, formulation of PVC pipe, and after-sales service, we take care of it all. At Benk Machinery, we value the terms of the contract and adhere to them strictly, and also provide pictures of our whole production progress to our clients step by step. We only produce top quality plastic extruding machinery for overseas clients, as all our machines are exported for our valued customers at board. Furthermore, we maintain one quality standard of machines for all clients, regardless of their location. All of them are happy to work with us, and to grow their PVC pipe business. At Benk, we always stock important parts based on their cash price, and we never buy goods with O/A, which is why we can produce our machines with acceptable price. All you need to do is tell us the PVC pipe sizes and the thickness you need, and we will supply the whole mechanism for you soon.

Chapter 2 : How do We make PVC Pipes, and What machinery is Used?

Before making PVC pipes, we need to make sure that we have the necessary equipment and personnel available. You would need PVC raw material, pipe plant, PVC pipe making machine and mechanical operators.

2.1 PVC Raw Material

You can buy raw material from your local market, or we can give you the PVC pipe receipt, using which you can mix the formulation by our hot and cool mixer in your factory. Whether you are new or familiar with the PVC pipe extrusion formula, our apex engineer will help you solve all problems. Here is a rough PVC supply water pipe formulation for your reference. If you can get a customized one from our sales team.

| Formulation | |

| PVC Resin Powder | 125 |

| Calcium Carbonate | 50 |

| Stabilizer | 5 |

| CPE | 4 |

| Stearic Acid | 0.5 |

| Paraffin Wax | 0.5 |

| Carbon Black | 0.2 |

To get a different color for the PVC pipe, you can add color powder in the formula. You also can buy the mixed formation raw material from your country or from a supplier in China, but it will increase your production cost. Once you get the idea of PVC pipe formulation, you can try the best economic formula for you, but you need to conduct tests many times in production. That is why big plastic pipe extrusion companies have a research and development team to find the best solution for them, so that their selling prices can be competitive in the market.

2.2 PVC Pipe Making Machine

Normally, we know that PVC pipe making machine is a whole production line which consists of PVC pipe extruder, extrusion mold, vacuum tank, haul-off (tractor), and stacker or collector. PVC pipe extruder is conical twin screw extruder; normally we have this type with different production capacities:

| Extruder | SJZ51/105 | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ80/156 | SJZ92/188 |

| Main motor | 18.5KW | 22KW | 37KW | 55KW | 55KW | 110KW |

| Capacity | 100-150 | 150-200 | 20-250 | 350-400 | 350-400 | 700-800 |

The SJZ51/105 and SJZ55/110 are mostly for customers who have a small budget for their production line. However, their production capacity is small, and this restricts you if you wish to make pipes of bigger sizes.

Conical twin screw extruder

Our most recommended model is the SJZ65/132, as it is preferred by most manufacturers. We also design a complete proposal, which has details of the setup and production cost, according to your budget.

2.3 Your Operator or Staff:

The operator is the one who can operate and manage your PVC pipe extrusion equipment for you. He should have ample experience in running and maintaining PVC pipe extrusion machines since it will consume a lot of time to train a newbie. He should also have knowledge of the normal temperature for each zone in the conical twin screw extruder and extruding mold. His troubleshooting abilities would be a big plus for you, as it will help you experience minimum downtime and improve turnover. He must be aware of all mechanical and electrical problems and should be able to fix them. Any kind of technical issue can set back your production schedule by anywhere between 3 to 6 hours, and you cannot afford this kind of downtime. You do not have to worry if you do not have competent operators. Our engineers train and instruct operators, and also provide video tutorials.

Chapter 3: Which Kind of PVC Pipe Making Machine do You Need?

Firstly, to determine the type of PVC pipe extrusion machine that you need, you need to tell the factory what kind of PVC pipe you want to produce. PVC pipes are of the following type, based on the material used:

- Plain PVC: The cheapest of all the PVC material, and it is easy to be formed.

- UPVC: The most commonly used PVC pipes that we see and find in the market. UPVC pipe is mostly used for drainage or sewage.

- CPVC: Also named chlorinated PVC, because it has a higher percentage of chlorine. CPVC pipe can be used in a broad range of applications.

- PVC-U: Has thicker walls which can undertake high pressure, so it can be used to supply and pump water.

- PVC-M: TA new type of PVC pipe. It has less thickness for PVC pipe wall, but it still can withstand high pressure like PVC-U, so it can save production cost for the manufacturer.

- PVC-O: Has the basic functions of a PVC pipe, but the walls are thin and the pipe out diameter is bigger.

Most customers are seeking UPVC or plain PVC pipe extrusion machine, as the cost for raw material and machine is much lower. From material characteristics, there are two types of PVC which are soft PVC and rigid PVC. Soft PVC is used to make small PVC pipe, of size range 10-32 mm. It is also called garden pipe or hose pipe. Rigid PVC is used to produce hard PVC pipe, of size range 16-630mm. Rigid PVC pipe can be used for water supply or pumping, for water waste transport and also as an electric conduit pipe. From the function of PVC pipe, it can be named following type: Agriculture Pipe: Rigid PVC tube to be used in farmland to transport water for crops.

Agriculture pipes in farmland

Water supply PVC pipe: Can supply pressure water for drinking purposes, but its wall thickness should be standard, and Calcium carbonate should not reach 30%. Electric conduit PVC pipe: Can be used to conduit electric wires in houses, apartments, or factories.

Electric conduit pipe

But its formulation will be different with water supply pipes. We need to add an anti-fire retardant in the receipt and more Calcium carbonate to reduce production cost. Industry transport pipe: CPVC pipe can be use as industry transport pipe, which can be used as hot sewage pipe in the factory, electroplating solution pipe, thermo chemical agent conveying pipe, wet chlorine gas pipe line of chloralkali plant. CPVC pipe machine is similar to the conventional ones you see in the market, but we need to change the designs for screw and barrel according to the application and installation. So the cost for CPVC pipe making machine will be a little higher than normal standard PVC pipe making line. After knowing the above information for PVC pipe, do you know which PVC pipe would you like to produce now? If you have clear idea, just send your requirements to us.

Chapter 4: How to Find a Reliable Supplier When You Are Ready to Buy Machines?

As we know that China is the biggest country to make PVC pipe machines, and the biggest plastic extrusion machine manufacturer is also located in China. Zhangjiagang city has become the largest manufacturer of plastic extrusion machinery in China. The city is only 150km from the Shanghai Pudong airport. A standard PVC pipe manufacturing machine has more than 100 parts inside it, and it is difficult to be familiar with all parts. However, it is not necessary for you to know all of them. You can focus your energy on your business, which will bring more profits for you. These are the important parts of the machine that you should know about:

4.1 Pipe Extruder:

The biggest parts for the conical twin screw extruder are the gearbox, screw and barrel, heater and cooling fan, driving motor, and electrics. Gearbox: We only use JC brand gearbox for twin screw extruder which is made by the top brand in China. You can find the brand name and pictures of gearbox here:

JC gearbox for conical screw extrusion mahchine

Screw and barrel: We have the drawing of screw, but we do not need to know which design of screw and barrel is suitable for us, as it is hard to understand without the required mechanical knowledge.

Conical twin screw and barrel

What we know is the process of its surface, whether they are bi-metallic or SKD-11. The cost of SKD-11 processing is higher than bi-metallic. Bi-metallic processing is suitable for your use. Driving Motor: Siemens brand is our prior choice, and it is AC type, but you should know that all Siemens brand is made in China.

Siemens driving motor

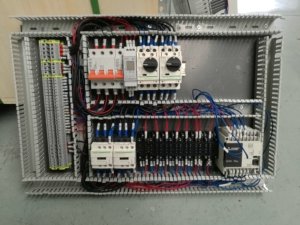

These are the brands of electric devices that we use in production, but you can also compare these with other brands.

| Name | Brand | Function |

| Contactor | Schneider D type universal | Control the circum |

| Air Switch | LS brand belong to LG group | Protect the circum when current is overload |

| Solid State Relay | Crydom from USA | Control circum to change its working status |

| Motor overload protector | GV2type-Schneider brand | Protect driving motor |

| Middle Relay | Omron brand | |

| Transformer | CHNT brand | Isolate circum to protect people |

| Temperature controller | Omron brand | Control the temperature in screw and mould |

| Button | Schneider brand | Control the extruder |

| 24V Power Supplier | Omron brand | Chang voltage for SSR |

Electrical equipments for extruder

As you know that PVC extruder is supposed to work non-stop in your plant, electric parts are very easy to be damaged if the quality is not good. You can find electric parts from international manufacturers in your market, but prices would be much higher than those in the Chinese market. We always recommend opting for our after-sales service, because you can also find counterfeit products in your local market. Anyway, we only need to know what brand they use in their machine when you are visiting PVC pipe extruding machine manufacturing factories in China.

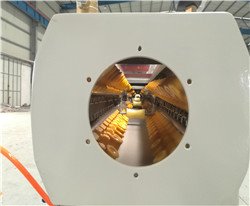

4.2 Extruding Die

For PVC pipe extruding die, it will be difficult to know the quality from its surface. You would need to use it several times to know its quality. The PVC pipe machine factory will choose the mold according to their experience, but we need to alter the length of mold head, as the quality will be better with longer lengths. The most used raw material is 40Cr. For the mould, we only need to know its raw material, as the wrong type of raw material may damage parts for the whole PVC pipe extruding line.

PVC pipe mold

4.3 Vacuum Tank

The most important factor for vacuum tank is the thickness of SS board, and the kind of SS used. As the SS board of vacuum tank is too thin, the shape of the tank will be changed by vacuum pump with the passage of time. In order to keep the original shape of vacuum tank, we would recommend you do the vacuum tank with the thickness of SS board.

| Size of Vacuum Tank | Thickness of SS | Material of SS |

| 20-63mm | 3mm | SS304 |

| 50-160mm | 3mm | |

| 160-250mm | 4mm | |

| 200-400mm | 5mm | |

| 315-630mm | 6mm |

PVC pipe vacuum tank

After knowing the board thickness in the vacuum tank, you also need to know about the vacuum pump and water pump. There are two factors for consideration, which are power for the different sizes of tank, and the brand name. The quality of Chinese water and the vacuum pump is good, but it is important to know which brand is good for us. The best brands in China are Guangyi and Yuhuan. When we know the brand of the water pump and vacuum pump, we need to know how to choose the power for different sizes of vacuum tank. Here is a full list for your reference:

| Size of Vacuum Tank | Power of Water Pump | Power of Vacuum Pump |

| 20-63mm | 3kw-2pcs | 2ww-2pcs |

| 50-160mm | 4kw-2pcs | 3kw-2pcs |

| 160-250mm | 4kw-2pcs | 3kw-2pcs |

| 200-400mm | 5.5kw-2pcs | 4kw-2pcs |

| 315-630mm | 7.5kw-2pcs | 5.5kw-2pcs |

Since there are two chambers in the vacuum in our factories, 2 pieces of each equipment is needed. However, many factories operate with only one chamber. You need to check this factor when you visit the factory. We use an LS air switch, a Schneider overload protector and contactor.

LS air switch, Schneider contactor and overload protector

You can compare details of two brands for pipe connection and footer in the vacuum tank. There is less difference between their costs, but the installation time and labor requirements are different. Now you can understand why different factories or suppliers give different offers, and it is also easy for you to understand the various parts of the vacuum tank.

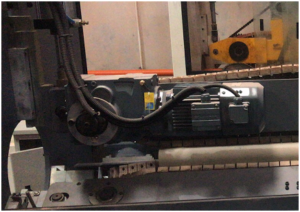

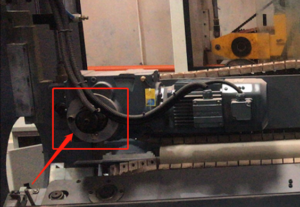

4.4 Haul-off

The haul-off has more than one type, and usually we make the type with each motor and reducer on each claw. There is a cheaper model which is driven by chain with only one motor. You can see their pictures, to understand the difference between them.

Motor and reducer on each claw Drive by chain with one motor The first one is more stable and without noise when working, and the motor and reducer are from ‘redsun’ brand, which is the top brand in China.

Motor and reducer on each claw Drive by chain with one motor The first one is more stable and without noise when working, and the motor and reducer are from ‘redsun’ brand, which is the top brand in China.

Redsun reducer and motor

In the above haul-off, you can see a device on the reducer which is an Autonics rotary encoder; it can calculate the length of pipe, and then send the data to the PLC.

Autonics Rotary Encoder

For electric parts, please kindly check following pictures. You only need to know the brands to be used in the motor. They are the same as electric parts in PVC extruder, which are the LS air switch and ABB inverter to control the driving motor.

Electric parts for Haul-off

4.5 Cutter

There are two types of cutter for different size pipes, which are the chip free cutter for 20-110mm PVC pipes, and planetary cutter for 110-630mm pipes. Cutter for PVC pipes One year ago, the lift cutter was used for 20-110mm pipes, which was very cheap, but it released a lot of powder, so it became obsolete.

Lift Cutter

Now, we recommend the chip free cutter (dust free cutter) for small pipes. Kindly check the pictures for the cutter.

Dust Free Cutter

Besides, there is no chamfer function in lift cutter, so we also install it in the dust free cutter. The cutter saw works together with the chamfer saw, as they are in the same shift.

Cutting Saw and Chamfer Saw inside

The dust free cutter also releases some dust, but it is in the form of chips, which settle on the ground rather than flying around. Planetary Cutter Planetary cutter is only used for 110mm plus pipes, and it consists of a rotary bearing, oil pump, and two driving motors. Here are some pictures of its internal details. One motor is used to drive the rotary bearing, and the other is for cutting the pipe. The oil pump is used to push the saw. Kindly check following picture:

Parts for planetary cutter

The electric parts are the LS air switch, Schneider motor overload protector, Schneider contactor, Mitsubishi PLC and Voltage overload protector. The Mitsubishi PLC (Programmable Logic Controller) is used to set up and carry out the actions on cutter. It can be used to set up the length of pipe, how long to cut, turnover time on stacker. Once we know the parts for planetary cutter, we need to make sure the two vertical boards should be parallel and plain; then the cutter can be used to cut the pipes normally. The cutting mouth could be smooth, as in the following pictures.

Electric devices for Cutter

4.6 Stacker

The stacker will be made as per the size of PVC pipes. It consists of cylinders, wheels, and steel pipes. We do not need to pay more attention on the stacker. We need focus on the core machines for the production line. After all of the above tips are followed for one production line, you don’t need to worry about the quality of the machines you buy, since the machines will be made according to the details. Benk Machinery will test all the machines in their workshop; you can find the following testing video for 110-200mm PVC pipes. If you still have any questions for the extrusion line, please email our support team.

Stacking frame

Chapter 5 : What Auxiliary Machines You Need When Buying PVC Pipe Making Machine

5.1 Mixing Unit

Earlier, we have mentioned the PVC formulation for PVC pipe. When we mix powder with other additives, we need to use hot and cool mixer to make pre-reaction for them. The mixing unit consists of hot mix and cool mixer, screw loader, and electric cabinet.

Hot and cold mixer

The parts we use in mixing unit:

| Driving motor | Simo- Chinese No. brand |

| Thickness of board for pot | 8mm |

| Inverter | ABB to protect driving motor |

| Raw material of blade | High quality alloy steel |

| Cylinder | AirTAC brand |

| OD of screw loader pipe | 106mm |

Working principle for hot and cool mixer: Hot mixer: Heating raw material by self friction and heater inside of pot, and then raw material will re-plasticize in the pot. Cool mixer: Raw material will be cooled by recycling water inside of pipe in tank. What are the benefits: As we install inverter for driving motors, it can work for a long time, and are highly efficient in mixing raw material without making too much noise. We use good seals in the mouth of each pot, so you do not have to clean up the powder in your workshop. When you want to buy the mixing machine, you need to know the capacity you need and the plan for your workshop. If you only want to invest in setting up one PVC pipe production line, you only need to buy one small mixer for your production line, but if you have plans to expand your factory, it is better for you to buy a big mixer like the SRL500/100, which can serve 2-3 PVC pipelines. When you buy the mixer, you can stick to the above parts, but if you want to know the format for different capacities for the mixer, please contact us.

5.2 PVC pipe Belling Machine

80% of manufacturers buy the pipe belling machine when they buy the PVC pipe production line, as it is the best and cheapest way to connect the pipes. There are two type of belling machine, which are automatic belling machine and manual belling machine.

Manual Belling Machine Automatic Belling Machine You can derive the difference between the machines from their names. Automatic belling machine can be connected with PVC pipe extruding line. You would need two operators on manual belling machine to push and pull pipe from heating oven and belling mold. So we recommend our clients to buy the automatic belling machine at the time of purchasing your PVC pipe extrusion machine. The parts we use in the PVC socket machine are:

Manual Belling Machine Automatic Belling Machine You can derive the difference between the machines from their names. Automatic belling machine can be connected with PVC pipe extruding line. You would need two operators on manual belling machine to push and pull pipe from heating oven and belling mold. So we recommend our clients to buy the automatic belling machine at the time of purchasing your PVC pipe extrusion machine. The parts we use in the PVC socket machine are:

| Siemens screen | To set up the working data for machine |

| PLC | Programmable Logic Controller |

| Cylinder | Stand up the pipe and catch the pipe |

| Hydraulic Station | Push the mold in the heated pipe |

When you buy the PVC pipe production line, it is better to ask the manufacturer to make the belling machine for you together, as it will reduce energy costs. You can have the auxiliary machine built from a trusted manufacturer in China, and it would save a lot of trouble for you.

Chapter 6 : How Much Does it Cost to Build the PVC Pipe Manufacturing Plant?

Many clients are not aware of the plastic extrusion process and extruder. But they do know that PVC pipes are selling like hot cakes in their markets, as many of them are distributor or wholesalers for plastic pipes. After knowing all the details for machine and its extrusion process, another headache will be to build your factory, and to determine how much area you need for your production line. After you confirm which size PVC pipe machine you need, we will supply the PDF proposal for you. Many clients have land and a workshop for the production line, but even then they need the drawing to see how to install the production line in their factory. The three necessary things you need in your factory for the PVC pipe production line are water, electricity, and gas.

6.1 Water:

You need to use recycled water in your factory. It is better for you to build a small water pool to store water in your factory. If you do not use recycled water, water will be wasted a lot for each production line. Because temperature of water in vacuum tank will be higher, you need to use the recycled water instead of plain water in vacuum tank. There are two ways to decrease the water temperature: one is to use chillers, but one chiller is only suitable for one or several production lines, and not for big pipe plant. When you use a chiller, you would need to dig or build a water pool.

Water chiller

The second way is to install a water tower on the top of the water pool, as it is much cheaper than chiller and can cool more production lines at one time.

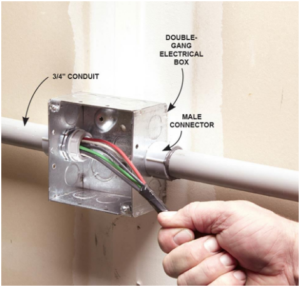

6.2 Electricity

Our experts will tell you the total power needed to run the PVC pipe making machine. When you wish to get a quotation from us, we also need to know the voltage information of the three-phase and two-phase in your country, but we have information from many countries now as per our observation. You only need one electric wire to connect with the power box in your factory, as we supply all electric wires for connecting different machines with the PVC extrusion machine. The air switch for the PVC pipe production line is located in the PVC extruding machine, so we only need have one electric wire to connect with your power box. Connection of all the machines is very easy for you. We use the plugs in both heads of electric wire, like we charge our computer or phones. Although it is not a big trouble for you, our aim is to solve your troubles as much as we can, and we always stand by our customers’ line to answer their questions. If you still have any other requirements for the production line, we will do our best to meet them.

6.3 Gas

The gas is supplied from an air compressor. It is the same way for all clients. You can choose the power of air compressor as per your quantities of production line.

Air compressor

We can help you get an idea of the quantities of production line, and the required air pressure for each quantity.

Chapter 7 : Buy New PVC Pipe Extrusion Machine or Old Machine – It is Your Decision

When you plan to build your PVC pipe plant, you would think whether to buy second hand machines or new machines. For many new clients, they will have doubt that whether buy new machine or old machines. If you are short of money for buying new machines, we might be able to find second hand machines for you in the Chinese market, but we cannot promise its quality. For used PVC pipe making machine, we only suggest clients to buy second hand conical twin screw extruder, and buy a new twin screw with the production line. If there is some problem with the screw, we have replacement parts. If you choose to consult with Benk Machinery, you can be assured of a hassle-free experience, where we will adopt your project, and make sure that you are able to set up your pipe manufacturing business smoothly. To know more about our machine, feel free to email our sales team. Reference: https://en.wikipedia.org/wiki/Polyvinyl_chloride