- Fast Delivery

- Power Energy Extruder

- Advanced Germany Tech

Twin Screw Extruder

| Contactor | Schneider Brand |

| Motor | Siemens Ac Motor |

| Temperature Controller | Omron Brand |

| Inverter | ABB Brand |

| Conical Twin-Screw and Barrel | Bi-metallic or SKD-11 |

| Heater | Cast Aluminum heater covered SS board |

| Gearbox | JC Gearbox |

| Cooling Fan | High-frequency fan with saving power |

Choose the Suitable Twin Screw Extruder for Your Extrusion Products!

Conical Twin Screw Extruder means two pieces conical shape work together in the barrel of extruder, it is used to produce PVC pipes, WPC profile, PVC pipes, PVC granules with different molds and down-stream machines. The conical twin-screw extruder has high pressure than single screw extruder. conical twin-screw extruder is widely used to produce high percentage of caco3 plastic or plastic compounded products.

Main tech data:

- Size: 45-110mm

- Length: 3-6meters

- Main motor power: 15-200Kw

Co Rotating twin-screw extruder is used for plastic compounding function and make PET granules, the screw is building block, we can change its permutations as your requirements on different material. The gearbox of the twin-screw extruder is high torque which max. 600rpm. Co rotating twin screw extruder is good function on mixing as well, we can add side feeder on the twin screw extruder directly.

Main tech data:

- Size: 20-160mm

- Output: 2-5000kg/h

- Main motor power: 3-1200Kw

Counter-rotating twin screw extruder is the mother of conical twin scrw extruder, counter-rotating twin screw extruder has a higher output than conical extruder, as it has higher rotating speed. Currently, we use the counter-rotating twin screw extruder in producing plastic profile, pipe and SPC floor sheet. The diameter of screw from 52-160mm, we can help you choose the suitable extruder for your products.

Main tech data:

- Size: 20-160mm

- Output: 2-5000kg/h

- Main motor power: 3-1200Kw

Your Premier Twin Screw Extruder Manufacturer

Benk twin screw extruder also named conical twin screw extruder which is used to make PVC profile, PVC pipe, PVC foam board, PVC marble sheet and PVC pellets, WPC profiles, and so on, but twin screw extruder need work with different downstream machines in the whole production line. Benk twin screw extruder machine is used the best parts from the Chinese manufacturer and some are produced by ourself, the quality is best among all China extrusion suppliers. The elements what we buy from local suppliers are gearbox, screw and barrel, ABB inverter, contactor and motor. Benk conical twin screw extruder’s principle is using is co-rotating by two conical screws in opposite directions in the barrel. The advantage of twin screw extruder is higher output and better plasticize plastic compared with single screw extruder. Benk twin screw extruder machine is only the extruder in PVC pipe extrusion machine, if you need whole extrusion line, please contact us, the whole PVC pipe extrusion line including the extruder, extrusion die, vacuum tank, tractor, haul-off, belling machine and stacker. Benk conical twin screw extruder also can be used in the plastic sheet extrusion line, we have supplied our PVC sheet making machine to many sheet extrusion companies in China and India, the sheet extrusion die is designed by T die. If you buy our machines, we will supply training operation for our machines, and we will inform you the about temperatures for different raw material, and we also can supply you the troubleshooting guide in the extrusion process.

- Data Sheet

- Videos

- Image Gallery

- Main Parts

- Send Enquiry

Different Tye for Conical Twin Screw Extruder:

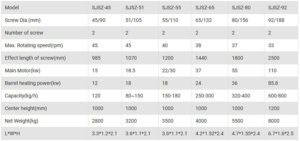

| Model | SJSZ-45 | SJSZ-51 | SJSZ-55 | SJSZ-65 | SJSZ-80 | SJSZ-92 |

| Screw Dia.(mm) | 45/90 | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

| Number of screw | 2 | 2 | 2 | 2 | 2 | 2 |

| Max. Rotating speed(rpm) | 45 | 45 | 40 | 38 | 37 | 33 |

| Effect length of screw(mm) | 985 | 1070 | 1200 | 1440 | 1800 | 2500 |

| Main Motor(kw) | 15 | 18.5 | 22/30 | 37 | 55 | 110 |

| Barrel heating power(kw) | 12 | 18 | 18 | 24 | 36 | 85.8 |

| Capacity(kg/h) | 120 | 80~150 | 150-180 | 250-300 | 320-400 | 600-800 |

| Center height(mm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1200 |

| Net Weight(kg) | 2800 | 3200 | 3500 | 4000 | 5500 | 8000 |

| L*W*H | 3.3*1.2*2.1 | 3.6*1.1*2.1 | 3.6*1.1*2.1 | 4.2*1.52*2.4 | 4.7*1.55*2.4 | 6.7*1.6*2.5 |

Videos to Show Our Twin Screw Extruder:

Brand and function for other electric parts:

| Name | Brand | Function |

| SSR | Crydom Brand with CE certificate | Control temperature for twin screw extruder and extrusion die |

| Overload Protector | Schneider Brand(Gv2 type) | Protect fan, the motor in the vacuum pump and water pump |

| Fused core | Bussmann Brand | Protect Heater and SSR Relay |

| Middle Relay | Ormon Brand | Control Electric Line |

| Switch | Schneider Brand | Switch on/off heating function |

| Ammeter | CHNT Brand | Checking heating electric line is working or not |

| Reactor | Riye Brand | Protect inverter when starting the machine |

| 24V power source | Ormon brand | used for SSR relay |

| Air Switch | LS Brand Belongs to LG Group | Protect Whole Electric Line |

| Isolate Transformer | CHNT Brand | Protect staff safe when they operate the machine |

| Inverter | ABB Brand | Protect Siemens Ac Motor |

| Vacuum pump | Chinese No.1 Brand | To take out water or moisture in barrel |

Twin Screw Extruder: The Complete Guide

If you are in the plastic pipe or profile, board or sheet industry, a complete guide into the operations of a twin screw extruder is all that you require. A guide that will ease the way you operate a twin screw extruder and make your operations efficient. Actually, we have two type twin screw extruder, which are conical twin screw extruder and parallel twin screw extruder, in this artile, we will talk about conical twin screw extrder for PVC, if you want to know more about parallel twin screw extruder, please click here. That is what this guide offers you. Not only will you find it easy to utilize this guide but you will learn about the terms of the double screw extruder. And that is not all. You will be able to learn the design as well as the working principle of the twin screw extruder.

Let’s read along to understand

What is a Twin Screw Extruder?

But wait, before we proceed, we need to define what a twin screw extruder is. https://youtu.be/7cnZPgEM9Tw A twin screw extruder refers to an equipment found in the plastic making industry. Its purpose is to mix and melt various polymeric materials to come up with a variety of plastic products. A unique characteristic of the twin screw extruder machine is that it has two screws inside the barrel. This helps in mixing the resins properly and ensure maximum heating.

Figure 1 Twin screw

Its flexibility allows for the designing of various plastic products. For instance, the screws can be, made to:

- Co-rotate

- Counter-rotate

- Intermesh or non-intermesh to suit a particular purpose.

But in our conical double screw extruder machine which is only counter-rotating type. There is a lot that happens during the extrusion process. To understand the details and the flexibility of a twin screw extruder, let’s read along.

Twin Screw Extruder Basics

What makes you choose a twin screw extruder over the other extruders? What are some of the advantages you will have when using this types of extruder? Also, what are some of the limitations you will have when using this extruder? You will find the explanation to these questions in this sections. This will enlighten you to choose the twin screw extruder for your operations.

Why you Need a Twin Screw Extruder?

An important question to ask when you want to purchase a twin screw extruder.

Figure 2 Twin screw extruder machine

To illustrate the importance of a twin screw extruder, here are some of the reasons of having a twin screw extruder.

· Safe delivery of water for consumption.

A twin screw extruder plays an important role in the manufacture of pipes that we use for safe delivery of water for consumption. Using the latest technology, pipes made from twin screw extruder are leak proof which avoids water contamination.

· Increase agricultural productivity

Agriculture plays an important in our survival. As such, constant irrigation is important. Twin screw extruders manufacture pipes for irrigational purposes. Pipes such as hose pipes and drippers are available due to a twin screw extruder.

· Pipes for oil transportation

Another reason why you need a twin screw extruder is that it helps in the oil industry. The availability of pipes from a twin screw extruder transport various oil products. This helps in avoiding accidents that relate to oil tanker collision which are very disastrous.

Advantages of a Twin Screw Extruder

Below are some of the main benefits of twin screw extruder you should know:

Figure 3 Corrugated pipes leaving the twin screw extruder

· Advance mixing ability

Twin screw extruders have different designs of the screw which have a wide interpenetration. This helps in properly mixing the resins. Different types of screws such as the kneading screws and the reverse screws allow for precise shearing of the resins. This allows for extruding materials which are uniform.

· Advance process flexibility

A twin screw extruder can handle several processing functions in one extruder. These functions include mixing, melting venting and cooking. This is made possible due to the interdependency of the screw sped.

· High productivity

Twin screw extruder has high productivity which is as a result of its ability to handle a wide range of raw materials. It also handles different mixing recipe at different screw speed.

· It is economical

A twin screw extruder is economical when you analyze its running cost. It utilizes less raw material while the output level is high. Also, the amount of energy consumption is low which ensures that you get the most out of your production. Not forgetting that since it is flexible, you can produce different designs of plastic pipes.

Disadvantages of a twin screw extruder

Like every machine, there are some challenges when you are using this machine. However, this cannot hinder you from choosing a twin screw extruder for your production. Let’s have a look at some of these limitations of a twin screw extruder

· The high cost of acquiring

The initial cost of acquiring the twin screw extruder when you compare to the single screw extruder is relatively high. This makes it unattractive for people to purchase

· Constant maintenance

Regular friction in the barrel means that the screws go through wear and tear. This means that there is a need for constant replacement of the screw. Another area where there are wear and tear is in the compression section, the rib edge and the barrel. This implies that you will have to replace this sections often. Lastly, if you want to get the best out of your twin screw extruder, you will have to pretreat the resins constantly. This ensures that your resins produce the best quality plastic products.

Parts of a Twin Screw Extruder

As equipment that you will often use, you need to understand the various parts of a twin screw extruder. Where these part are, and their purpose is very important.

Figure 4 Different parts of twin screw extruder machine

In this section, we are going to look at the definition of these parts to enable you to identify them. Let’s read along.

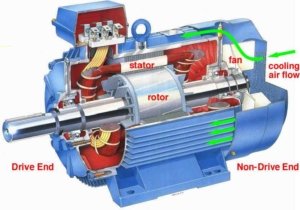

i. Motor- Simens motor

Your twin extruder needs the energy to power up. This energy comes from an electric motor. An electric motor converts electric energy into mechanical energy. It is this mechanical energy that all operations in the twin extruder will utilise. There are different types and models of electric motors that depend on the size of your twin screw extruder.

Figure 5 Electric motor

So in case, your production is relatively small, your twin screw extruder will have a small electric motor. Another thing to note is that the amount of energy that your extruder consumes depends on the size of your motor.

ii. Conical Twin-Screw and Barrel

The twin screw extruder has two screws whose function is to propel materials forward. This helps in the distribution of heat to the resins in a uniform manner. There are different types of twin screw that you can use. This includes co-rotating screws in which the screws are rotating in the same direction. We also have the counter rotating screws where the screws are rotating oppositely.

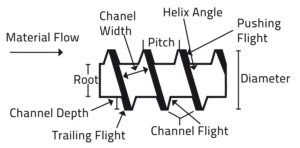

Figure 6 Different styles of plastic extruder screws

The screws are said to be intermeshing when centerline between the shafts of the screws happens to be less than the screws diameter. If the centerline between the shafts of the screws is the same as the screw diameter, the screws are non-intermeshing. The barrel hosts the screws, and they are responsible for feeding molten resins to the die which builds pressure on the die. You can use co-rotating twin screw extruders in high speed when you want to compound resins with additives. You can also use it when you want to remove solvents. If you are using co-rotating twin screw, you can produce pipes and profiles. On the other hand, you can use counter rotating screws when you want to compound PVC and other resins.

Figure 7 Parts of the screw

When it comes to Non-intermeshing, counter-rotating screws, you can use them in de-volatilization and chemical reactions. On the other hand, the barrel conduct heat from the heaters underneath it which distributes it distributes to the resins. Different types of barrels exist such as

- The vented barrel which has an opening at the top for feeding

- A combo barrel which has a feeding at the side and a vent at the top.

- A solid barrel

iii. Heater

The function of the heater is to provide heat to the barrel. It is this heat that heats up the barrel which in turn melts the resins. Heaters are normally along the barrel, so that conduction of heat occurs. Different types of heaters exist depending on the temperature requirements and the applications.

Figure 8 Plastic extrusion process

For instance, the temperature range for aluminum heaters is 660°F. On the other hand, the temperature range for aluminum/bronze alloy heaters is 840°F

iv. Gearbox

The function of the gearbox is to convey energy from the electric motor to the screws. It also regulates the motor speed to align with the speed of the screw. As it does this, it multiplies the torque while multiplying the angular timing of the screw.

Figure 9 Gearbox – Photo Courtesy: Photo courtesy: WEBER

The connection of the shaft of the motor to the gearbox input shaft by the mechanical torque reduces damages to the gearbox. The connection disengages and engages automatically at pre-set levels.

v. Cooling Fan

The function of the cooling fan is to provide the necessary temperature control that the twin screw extruder needs to operate. There are two types of cooling fans available for the twin screw extruder. There is a cooling fan that uses cooling bores which are throughout the barrel next to the barrel liners.

Figure 10 Cooling fan

We also have a cooling fan that uses water. This type has a water loop running over the heaters.

vi. Vacuum pump

The vacuum pump section of the twin screw extruder us where the plastic products cool slowly to have their shapes. Abrupt cooling may result in deformation of the product.

vii. Hopper-Double screw feeding system

A hopper- double screw feeding system acts as surge bin that ensures homogenous flow and mixing of the resins.

Figure 11 Plastic pipe extrusion process

This ensures a uniform spread of the resins as they flow through the die ensuring quality products.

viii. Screw loader

A screw loader is an equipment which gives the screws a forwards push enabling the transportation of the resins forward. There are different types of screw loaders which depend on the type of screws that you are using.

ix. Electric cabinet

The electric cabinet houses the various electric components of the twin screw extruder. This includes the temperature controls, the feed speed controls and the failure warning elements of the extruder.

x. Air switch-LS brand from LG group

The air switch serves the purpose of minimizing the effects of electric faults when they occur. The LS brand from LG group is the best brand of an air switch in the market.

xi. Temperature Controller- Ormon brand

Controlling the temperature of the twin screw extruder is important. At optimum temperature, the resins can melt uniformly thereby giving you a perfect result. You can achieve this by using the temperature controller which are in the cooling and heating elements of the extruder. Its use also helps to prevent the warping of the plastic product. You can check out the Ormon brand of temperature controllers for a perfect temperature controlling unit.

xii. Inverter-ABB brand

For the twin screw extruder to function, the inverter converts the direct currency coming from the source of power to alternating currency. The direct currency is normally of low frequency hence the need to convert it to alternating currency which is of high frequency. Different brands exist, and the choice of brand to use depends solely on you. However, ABB Brand is the best when it comes to twin screw extruders.

xiii. Contactor-Siemens brand

The purpose of the is Siemens brand of a contactor is switching an electrical power circuit. A contactor is ideal when your twin screw extruder is a high current loader.

xiv. Solid State Relay- Crydom from the USA

Solid state relays refer to an electronic switching device. The purpose is to switch the twin screw extruder when you apply an amount of voltage over its control terminals.

xv. Switch- Siemens

The switch controls the operations of the twin screw extruder. Its use includes allowing and stopping the machine to operate. Siemens brand is the best when it comes to twin screw extruder switches.

Twin Screw Extruder Design

Now that you have learned of the specifics of a twin screw extruder let’s have a look at the technical specifics of a twin screw extruder. This involves what models are available and a pictorial illustration of a twin screw extruder. Let’s get into the details.

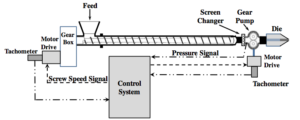

· Twin Screw Extruder Diagram

Twin screw extruder for plastic come in a range of shapes and designs. Therefore, it is upon you to choose a machine that is efficient and reliable.

Figure 12 Twin screw plastic pipe extruder

You can compare BENK Twin screw plastic pipe extruder with this:

Figure 13 Twin screw plastic pipe extruder

· Plastic Twin Screw Extruder Technical Specifications

Having had a look at how a twin screw extruder works, it is important that you understand the available models available and their specifications. This section details the specifications of the models available to help you in choosing the right extruder for your production.

Figure 14 Different models of twin screw extruder

Have a look. Before we start, you need to understand the unique characteristics of the twin screw extruder models. That is all extruders have two screws, and the center height is 1000mm. Now here is a look at the individual models of a twin screw extruder

· SJSZ-45

Using this model, you will notice that it has a motor power consumption of 15kW and a barrel heating power of 12kw. The maximum rotating speed of this model is 45rpm while its effect length of screw is 985mm. You will notice that its screw diameter is 45/90mm which gives you a production capacity of 120kg/h. You cannot ignore the weight and dimension of this extruder. The SJSZ-45 model weighs 2800kg, and its dimensions are 3.3*1.2*2.1.

· SJSZ-51

The SJSZ-51 model weighs 3200kgs and measures 3.6*1.1*2.1. The output capacity you will get from using this model is between 80-150kgs/h. When using this model, your motor will consume the power of 18.5 kW while the barrel heating power will be at 18kw. The effective length of the screw for this model is at 1070mm, and its screw diameter is 51/105mm. Lastly, the maximum rotating speed you can get from this screw is 45rpm.

· SJSZ-55

The SJSZ-55 model comes with a screw diameter of 55/110mm and rotates at a maximum speed of 40rpm. The motor power consumption of this model is at 37kW while the barrel heating power is 18kW. You will notice that the weight of this model is 3500kgs while its dimension stands at 3.6*1.1*2.1. Another feature of this model is that the effective length of the screw is 1200mm and it has an output capacity of between 150-180kg/h.

· SJSZ-65

This model will give you an output capacity of between 250-300kg/h while the motor will consume 37kW. When it comes to the weight and dimension, it weighs 4000kgs while its dimensions are 4.2*1.52*2.4. The barrel consumes 24kW of heating power. If you check at the screw diameter, this model has a screw diameter of 65/32. Another aspect of this model is the effective length of the screw which stands at 1440mm while its maximum rotating speed is 38rpm.

· SJSZ-80

The SJSZ-80 comes with a screw diameter of 80/156mm and a maximum rotating speed of 37rpm. The motor consumption of this model stands at 55kW while the barrel heat consumption is at 36kW. You will have an output capacity of 320-400kgs/h when using this model which weighs 5500kgs. Lastly, the dimensions of this model are 4.7*1.55*2.4 with an effective length of the screw of 1800mm.

· SJSZ-92

Another model of the twin screw extruder is the SJSZ-92 which weighs 8000kgs and has dimensions of 6.7*1.6*2.5. The motor of this model consumes 110kW of energy while its barrels consumes 85.8kW of heat energy. If you are accessing its performance, this model has an output capacity of between 600-800kgs/h. Another feature is the screw diameter which stands at 92/188mm while the screw itself gives a maximum rotating speed of 33rpm. Lastly, the effective length of the screw is at 2500mm.

Working principles of a Twin Screw Extruder

You have learned about the design of the twin screw extruder, but how does this type of extruder works? Which part of the extruder handles a particular process? This section aims at discussing these questions so as answer them precisely for you. Let’s get straight to the point.

Figure 15 Working principle of twin screw extruder

To understand how the twin screw extruder works, allow me to break it into the following sections:

· Intake zone

What basically happens here is that there is an intake, compressing and conveying of raw materials. These raw materials can either be resins or pellets. You can choose to add additives at this stage if you want to give yourself unique product characteristics. As the compressing goes on, removal of air takes place such that there is no air on the materials. Resins are fed into the twin screw extruding machine through the hopper and get into the screw via the feed throat. The screw then moves the materials forward. The intake capacity depends on some factors including the screw speed, the density of the resins. It also depends on the channel depth and pitch of the screw. Remember, materials can only move forward if friction occurs between the resins and the barrel.

· Melting zone

Once the materials are in the screws, the extrusion process begins. The screws keep pushing the resins forward. As this happens, friction occurs between the materials and the barrel which melts the resins. Extra heat comes from the heaters which are beneath the barrel. This ensures that the resins melt completely. One thing you need to note here is that as the resins move forward, the channel depth keeps decreasing thereby increasing the friction and pressure in the barrel. Different types of twin screw work together in this section. You have the co-rotating and the counter-rotating screws.

· Metering zone

Once the melting of the polymer is complete, they exit the extruder via a breaker plate which has screens. These screens help in removing impurities from the molten polymer. It is also here that the melting of particles which didn’t melt at the melting zone happens. This ensures uniformity of the molten resins. You can manipulate the number of screens and porosity of the screens if you want to achieve plastic uniformity. Also while here, the molten polymer come out in straight lines thereby eliminating the spiral effect on polymers. The pressure in this section is high enabling the molten polymer to extrude continuously and form shapes. In this section, there is pumping of air to prevent the plastic product from collapsing.

· Cooling zone

The plastic products move to the cooling zone where cooling takes place. There are two types of cooling systems which you can use. There is the air and water cooling system. Depending on which type of cooling system you use, your plastic products cools slowly. This enables the plastic products to form perfect shapes and also gives it the appeal they deserve.

· Final touches

After cooling, you may add any final touches you would like such as painting to your plastic pipes. You can after that arrange your pipes in a stacker.

Applications of a Twin Screw Extruder in Plastic Extrusion Industry

When it comes to the plastic extrusion industry, there are various areas where you can apply a twin screw extruder. This section takes a look at some of the areas where you can use a twin screw extruder. Figure 16 PVC Pipes Read along.

· PVC Pipe

PVC pipes are a common application to us. You can use this pipes in a wide range of areas. For instance, the application of these pipes is in the water distribution system. In this area, you lay the PVC pipes underground in a system which ensures transportation of water into buildings. You can also use PVC pipes in the sewer system which ensures safe transportation of human waste. In the construction industry, the application of the PVC pipes is in the construction of gutters, downpipes and drainpipes. The low cost of purchasing them and the low maintenance makes them ideal for this purpose. Not forgetting that the PVC pipes hardly leak which ensures no contamination.

· PVC Profile

Another area where you can use products from the twin screw extruder is in the PVC profile. You can apply this when you are constructing bath doors. Partitioning and decorating of your home. Also, you can use PVC profile when you are making window office sealing. The advantage you have here is that the PVC profile is durable, cheap to maintain and they are energy efficient.

· PVC Door Board

PVC door board reduces our reliance on the use of a wooden door when it comes to construction. You can use PVC door board when you are making doors for your office or home. When you compare with the wooden doors, PVC door is easy to install, cheap to buy and are durable. The PVC doors are eco-friendly and have a thermal insulation effect which protects you when using it.

· Wood-plastic Profile (PE-Wood Profile and PVC-wood Profile)

Another product you can make using a twin screw extruder is the wood- plastic profile. This is where you mix the polymer with wood fibre creating a profile that has the qualities of both wood and plastic. That is you mix the strength of wood using wood fibres and the affordable, flexibility and affordable characteristic of a PVC. The resulting product is waterproof thereby hard for it to rot as well as split as is the case with normal timber with moisture. You can apply this product in floor construction especially in areas susceptible to water

· PVC-wood Door Board

PVC- wood door board is a product of mixing of plastic and wood fibres. These door boards are durable, flexible and have a glossy appeal. You can use these boards when you want doors that have a luxury appearance.

· PVC Marble Sheet

The main materials that you can use when you are making the PVC marble sheet are PVC and calcium carbonate. These materials mix with chemical additives using a twin screw extruder to come up with quality PVC marble sheet. You can use these PVC marble sheet when making walls especially in the Kitchen or in the office. You can also use them when flooring your building. They make the structure to have a glossy, quality appeal.

· SPC Flooring

SPC refers to stone plastic floors which you can use to make floors. It gives an appealing appearance, and it is eco- friendly. Unlike other plastic products, the SPC floors do not expand nor contract hence suitable for flooring. Another advantage of SPC floors is that they are cheap and easy to install.

Twin Screw Extruder Supporting Equipment

Some equipment plays a vital role in making sure that your twin screw extruder works properly. This section looks at this equipment and their functions.

Figure 17 Illustration of plastic pipe extrusion

· Mixer

Your resins need to mix properly to ensure homogeneity of the mixture as it melts. The mixer does this. You can fit your mixer with a shredding die to ensure that the materials are broken up properly during mixing. The advantage of this is that it ensures maximum exposure of the particles for de-airing.

· Extrusion die

Towards the end of your twin screw extruder, there is the extrusion die. Some of the functions of the extrusion die include:

- To shape the molten plastic to give it a perfect shape.

- Controlling the molecular orientation of the plastic to give it its physical properties.

- To control the aesthetic surface of the product.

The design of the die affects the quality of your plastic products. There are factors which affect the productivity of your extrusion die. They include:

- The ratio of the screw cross section to the die cross-section.

- The size of the die which forms the shape of the plastic product.

- The nature of the material that forms the die when you are looking at the friction which occurs within the die.

· Haul-off

Haul- off unit is a device found at the rear end if the twin screw extruding equipment. Its purpose is to help in pushing the pipes forward during extrusion. You will find different models of this device which depends on the size you extruder and level of production.

· Cutter

When your plastic products exit the twin screw extruder through the die, there is a machine that trims it to size. This is the cutter which you can find just after the extrusion die. There are factors which you affect the cutter. These are the blade shape, thickness, cutting speed and the cutting method. Also, there are different cutters which depend on the type of product, the application of the product and the raw materials.

· Stacker

Your pipes will need to be in order after production. You can achieve this by using a pipe stacker. This is an equipment that arranges all your pipes after production in an orderly manner. This is an important equipment in that it prevents your pipes from breaking. Normally, you can locate this equipment at the tail end of your extruding machine.

BENK Twin Screw Extruder

You can use BENK twin screw extruder to produce a wide range of items such as PVC profile, PVC pipe, and PVC foam board. Also, you can produce PVC marble sheet, PVC pellets and WPC profiles.

Figure 18 BENK PVC Pipe Extrusion

The flexibility of these extruders is what makes them have such wide usage. We produce some of the parts for the BENK twin screw extruder ourselves while the rest we buy from quality manufacturers. Some of the parts that we buy include gearbox, screw and barrel, motor, contractor and ABB inverter. This ensures production of quality BENK twin screw extruding machine for you. The principle that BENK conical twin screw extruder use is that of counter-rotating the screws while in the barrel. This gives a higher output while ensuring production of well plasticize materials We sell the BENK twin screw extruding machine as a unit. However, you can get in touch with us if you want parts such as the extruder, extrusion die, stacker and vacuum tank. You can also use BENK twin screw extruder in plastic sheet extrusion lines. We do supply to extrusion companies in China and India as well as to other parts of the world. Purchasing BENK twin screw extruding machines guarantees you training operations from us. We will also provide you with troubleshooting guidelines for the BENK twin screw extruder. Not forgetting a tip on the different handling of different raw materials for the twin screw extruder

Conclusion

I am sure you have learned all there is about a twin screw extruder. The next step is to purchase one from a reliable manufacturer. If you are looking for that a manufacturer with experience, you will find that at BENK. Get in touch with us today and let us provide you with our different models of twin screw extruders. We guarantee you of originality of our products which come with a warranty.