- Normal Speed HDPE Pipe Extrusion line

- High-Speed HDPE Pipe Extrusion Machine

- Overall Services on Producing Machines and Factory Layout

First Choose HDPE Pipe Extrusion Line Manufacturer

| Extruder | Single screw extruder |

| Extrusion die | Normal standard or high-speed die |

| Vacuum tank | 9meters or 5.6meters with two segments |

| Spray tank | 9meters or 5.6 meters with one water pump |

| Haul-off | Two claw to 12 claws |

| Cutter | Non-dust cutter or planetary cutter |

| Collector | Stacker or Disc winder |

| Printer | Laser printer |

Choose the Reliable HDPE Pipe Extrusion line Factory to Save your Trip Cost in China!

BenK 16-63mm HDPE pipe extrusion line is used to produce HDPE water and gas pipelines, it can produce 1/2 inch to 2.5 inches, Benk produces the HDPE pipe extrusion line manufacturer more than 15 years in Zhangjiagang city, the max. production speed can reach 22max. Benk has normal speed and high-speed HDPE pipe extrusion line for your choose, and we has a different price level to meet different clients’ demands. For calibration sleeve, we have news design for high-speed production.

Main tech data:

- Size: 30m x 2m x 3m

- Whole line power: 130Kw

- Production capacity: Max. 400kg/h

BenK 20-160mm HDPE pipe extrusion line also has high-speed and normal speed, the capacity of high-speed HDPE pipe extrusion machine can reach 400kg/h, the normal speed is 250kg/. You can choose servo motor or AC motor on three claw haul-off. We can supply the testing report for you when machine is finished in our factory, we also can supply the production process flow for installation in your workshop. Welcome to ask the free offer!

Main tech data:

- Max. speed: 22m/min

- Plastic Extruder: SJ60/38 single screw extruder

- Vacuum tank length: 9meters or 6meters

BenK is a professional HDPE pipe extrusion line factory which is nearby Shanghai, 2 hours by car. HDPE pipe extrusion line can produce 3-10inch HDPE pipes with two sets of HDPE pipe extrusion die. HDPE pipe extrusion line including extruder machine, extrusion tool, vacuum calibration tank, spray cooling tank, tractor, and stacker. Benk can supply good quality HDPE pipe extrusion line and the best after-sale service.

Main tech data:

- Max. output: 640kg/h

- Plastic Extruder: SJ75/38 single screw extruder

- Plastic extruder motor power: 160Kw

Benk can produce a 200-450mm HDPE pipe extrusion line, and we have one layer and multi-layers HDPE pipe extrusion machines. Benk uses Siemens PLC and Schneider contactor in the HDPE pipe extrusion line. The advantages of 200-450mm HDPE pipe production machine is power energy and working stablely every day.

Main tech data:

- Max. output: 1000kg/h

- Plastic Extruder: SJ90/38 single screw extruder

- Plastic extruder motor power: 250Kw

Benk can export 5sets 315-630mm HDPE pipe extrusion line to over the world every year. Currently, we adopt all the best brand spare part on our HDPE pipe extruding machine, which can extend the service life of HDPE pipe extruding line.

Main tech data:

- Max. output: 1000kg/h

- Plastic Extruder: SJ90/38 single screw extruder

- Plastic extruder motor power: 250Kw

400-800mm HDPE pipe extrusion line is the big plastic pipe production line, which can produce 16inch to 32 inches. we can supply SDR11 and 17 extrusion die for you. Total length of production line is more than 50meters, and benk can supply production line drawings to you.

Main tech data:

- Max. output: 1200kg/h

- Plastic extruder motor power: 315Kw

- Quantity claw of haul-off: 8claws

- Plastic extruder: SJ120/38 single screw extruder

Benk had been exported 3sets 710-1200mm HDPE pipe extrusion line before, and all clients are still use them well. Benk adopts Germany technology in the HDPE pipe producing line, which has higher production capacity than other plastic pipe manufacturers.

Main tech Data:

- Max. output: 1600kg/h

- Plastic extruder motor power: 410Kw

- Quantity claw of haul-off: 8claws

- Plastic extruder: SJ90/38 and SJ75/38 single screw extruder

Your Premier HDPE Pipe Extrusion Line Manufacturer in China

BENK HDPE pipe extrusion line also named HDPE pipe manufacturing machine which is using extrusion process to make HDPE water pipe and PE sewage pipe. Benk factory had supplied many HDPE pipe machine to HDPE pipe manufacturing plants in China and overseas markets. If you want to know how to make HDPE pipe, please send email to us, our sales team will send your HDPE pipe manufacturing process video for our clients in our factory.

BENK always supply HDPE pipe manufacturing process flow chart to our clients in order to make good understanding for our plastic extrusion machines and guide them how to make HDPE pipe by themselves.

BENK HDPE pipe extrusion line is consisted by single screw extruder machine, and downstream machines as per the out diameter of HDPE pipe you need. Benk also can assist you to calculate how much you need invest for HDPE pipe plant in your country.

BENK is a leading professional pipe extrusion machine manufacturer who can supply good prices for HDPE pipe extrusion line, and we supply continue service for our clients when they meet problems in tube extrusion process in their pipe plants.

BENK HDPE pipe manufacturing machine can produce HDPE solid wall pipe with OD from 16-1200mm, the production capacity range will 150-1500kg/h.

If you want the HDPE pipe plant project report, please contact us for more details. Thanks.

- Data Sheet

- Videos

- Image Gallery

- Send Enquiry

Production Range for HDPE Pipe Extrusion Line:

| Model | Pipe range(mm) | Capacity

KG/H |

Extruder | Type |

| PE63 | φ16-φ63 | 350-450 | SJ60/38 | Double out |

| PE125 | Φ32-φ125 | 350-450 | SJ60/38 | Single out |

| PE250 | Φ75-φ250 | 500-650 | SJ75/38 | Single out |

| PE315 | φ110-φ315 | 850-1000 | SJ90/38 | Single out |

| PE450 | φ160-φ450 | 850-1000 | SJ90/38 | Single out |

| PE500 | φ200-φ500 | 850-1000 | SJ90/38 | Single out |

| PE630 | φ250-φ630 | 850-1000 | SJ90/38 | Single out |

| PE800 | Φ500-φ800 | 1000-1200 | SJ120/38 | Single out |

| PE1200 | Φ710-φ1200 | 1500-1800 | SJ75/38 + SJ90/38 | Single out |

The testing video for HDPE pipe extrusion line:

HDPE PIPE EXTRUSION MACHINE: THE ULTIMATE BUYING GUIDE FOR YOU

With our technology developing day by day, many products are instead of plastic products, now plastic pipe is very important in our life every day.

So, today we will talk about PE pipes made by HDPE pipe extrusion machine.

Many years, we still use the metal pipe to send our water to everyone’s house, but the metal pipe will get rusty when it touches with water, the rusty will damage our health.

Then, people try to find PE pipe to instead of metal pipe, and PE pipes have a longer service life, and much safer to send water.

Do you know what machines to be used to make PE pipes?

It is HDPE pipe extrusion machines.

Figure 1: HDPE pipe extrusion machine

Chapter 1: What is the meaning of HDPE material and HPE pipe extrusion machine?

What is HDPE:

HDPE is high-density PE, and PE is a short word of polythene which is a kind of plastic raw material, it is non-toxic plastic and been used in our life widely.

The most are PE pipes, and HDPE is Corrosion protection, which can be used more than 20 years when sending transport water or oil.

PE normally has two types, which are LDPE and HDPE, HDPE is mainly been used in making pipes, as it has more power to stand the pressure.

LDPE is mostly to be used in making the film for packing and make bags, sometimes people also use it to make a pipe, but they used it to make garden pipe and the very small pipe.

Figure 2: HDPE granules

The advantage of PE material:

- Weight is lighter than metal

- It is non-toxic for people

- Easy to clean and recycle

- Big volume in the world

The disadvantage of polyethylene material:

- Not anti-fire

What is HDPE pipe extrusion machine?

HDPE pipe extrusion machine is also HDPE pipe making machine which uses the single screw extruder to melt and plasticizing the HDPE raw material, and HDPE pipe formed pipe mold.

HDPE pipe extrusion machine is widely used to make different size HDPE solid pipe, if you want to make corrugated HDPE pipe, the downstream machine is different with HDPE pipe solid machine.

Chapter 2: Processing guide to make HDPE pipe?

We know that even we already have the HDPE pipe machine, we still cannot make HDPE / PE pipes, what others we need?

1. HDPE raw material

The raw material is HDPE pellets, maybe when you buy the raw material from your market, the color is normal black, but some client maybe buys the transparent or white HDPE raw material, like Saudi Arabia market.

When you buy new HDPE raw material, the color is always white, the recycled HDPE material is black.

Because, when you go the market, you always see black HDPE pipes, as they add black color master batch with HDPE raw material.

Figure 3: HDPE pipe making machine

2. HDPE pipe extrusion machine

I am sure you can hear that there are normal speed and high-speed HDPE pipe making the machine from HDPE pipe extruding line manufacturer, so what is the different between them?

I will use a chart to show them firstly.

Normal speed pipe production line:

| Pipe sizes | Capacity kg/h | Extruder size | Type | Motor power |

| 20-63mm | 120-150 | SJ60/33 | Single out | 55Kw |

| 75-250mm | 250-320 | SJ75/33 | Single out | 110Kw |

| 250-400mm | 350-450 | SJ90/33 | Single out | 160Kw |

| 315-630mm | 600-800 | SJ120/33 | Single out | 280Kw |

| 500-800mm | 800-1000 | SJ150/33 | Single out | 355Kw |

| 710-1200mm | 800-1000 | SJ150/33 | Single out | 355Kw |

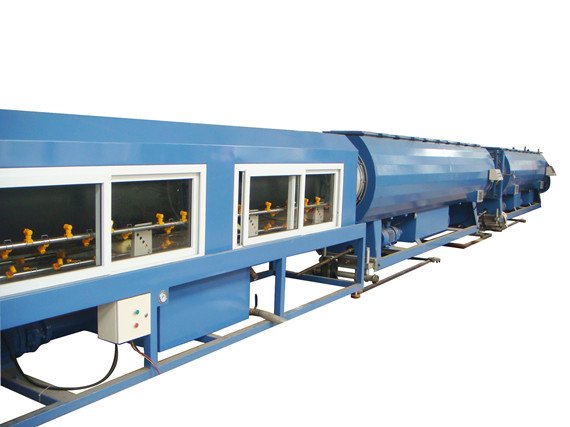

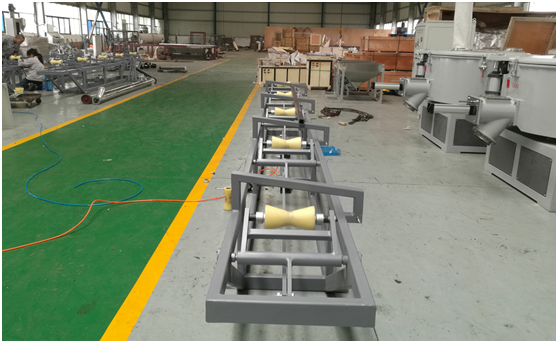

Figure 4 Normal speed HDPE pipe extrusion line

High speed HDPE tube extruder machine:

| Pipe sizes | Capacity kg/h | Extruder size | Type | Motor power |

| 20-63mm | 350-450 | SJ60/38 | Double out | 110Kw |

| 32-125mm | 350-450 | SJ60/38 | Single out | 110Kw |

| 75-250mm | 500-650 | SJ75/38 | Single out | 160Kw |

| 110-315mm | 850-1000 | SJ90/38 | Single out | 250Kw |

| 160-450mm | 850-1000 | SJ90/38 | Single out | 250Kw |

| 200-500mm | 850-1000 | SJ90/38 | Single out | 250Kw |

| 250-630mm | 850-1000 | SJ90/38 | Single out | 250Kw |

| 500-800mm | 1000-1200 | SJ120/38 | Single out | 315Kw |

| 710-1200mm | 1500-1800 | SJ75/38 + SJ90/38 | Single out | 160Kw+315Kw |

| 1000-1800mm | 2000-2600 | SJ90/38+ SJ90/38 | Single out | 315Kw+315Kw |

From the above data, I think you can find their output and L/D of single screw extruder are different.

The advantage of high-speed HDPE pipe machine adopts high torque screw and barrel and gearbox, that is why it can save power in the same output, or it can have higher output in same unit power.

But, high-speed HDPE pipe extruder line is more expensive than normal speed extrusion machine, as all material and structure of gearbox, screw, and barrel need high quality and high standard in production.

In the beginning, the client may be thought High-speed HDPE pipe extrusion line is more expensive, but from long-term views, it will more competitive for you in the market.

Figure 5 High speed HDPE pipe machine

At present, European and North American client would like to choose high speed HDPE pipe line, for developing country, they still like to choose normal speed.

In my opinion, when you make small pipes, it is better to choose high speed pipe extruding machine

What other different between high speed and normal speed PE pipe producing machine?

The length of a production line is also much different because their vacuum tank is different, we use 9meters length two chambers vacuum tank in high-speed HDPE pipe extrusion line with a better cooling effect.

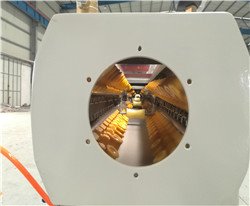

Figure 6: 9meters vacuum tank

The haul-off is also different, we will use the servo motor in the high-speed PE pipe making the line, and we will use the normal motor in the normal speed PE pipe making the machine.

Do you know why?

Because the production speed of high-speed PE pipe production line is very fast, we should use the servo motor to control the speed very accurate, then we can easy to adjust the speed of haul-off with the same speed of production line.

Figure 7: KraussMaffei rubber block design for Hual-off and servo motor

Chapter 3: How is HDPE pipe made and its extrusion process?

- I am sure you cannot wait how to make HDPE pipe now, let us see one video now.

The HDPE pipe is made by single screw extruder and connected with down-stream machines.

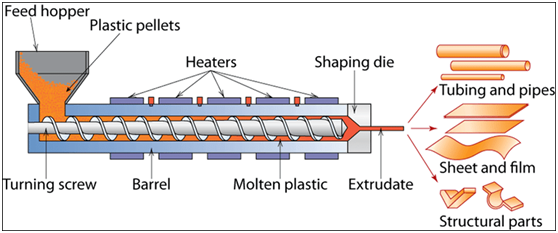

Figure 8 HDPE pipe manufacturing process

The single screw extruder is used the high temperature to melt the HDPE pellets and plasticize the HDPE in its screw and barrel.

The HDPE pipe will be formed by designed sizes molds, the HDPE pipe molds can be made with range, it means that one plastic pipe mold can make several sizes, but the gap cannot very big.

The soft HDPE pipe will come out from the pipes,

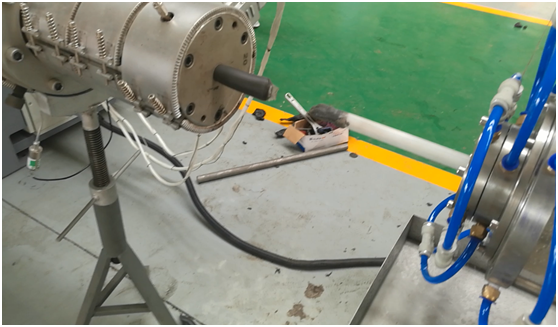

Figure 9 Soft HDPE pipes comes from mold

How to pull the soft pipes from mold to the vacuum tank, please note that the temperature is high, we cannot use our hand to touch the soft HDPE pipes.

We will use the similar size plastic pipes to pull the soft pipe into the vacuum cooling tank.

But the speed, cannot very fast, I will show the video how to pull the pipes.

After the HDPE pipe can be reached to our haul-off, we can pull out the plastic guide pipe.

For small HDPE pipe like 12-110mm, we will use the disc winder to collect them in the coil.

Figure 10 Double Disc winder

For more big size PE pipes, we will use the stacker to collect it. The length of HDPE pipe can be set, normal length is 6 meters.

Figure 10 Stacking racker

Chapter 4: How to find the best price for HDPE pipe extrusion machine?

After learning some acknowledge of HDPE raw material and HPDE pipe making the line, maybe you have a little interested in the HDPE pipe production line.

But for the initiator, please read this chapter carefully, I am sure it will save much money for you if you are planning to buy the HDPE pipe manufacturing machine, and you want to build your HDPE pipe plant.

How to recognize what they used in the HDPE pipe extruding line?

In my many year experiences, the most important is for single screw extrusion machine, as it is the vital part for the whole PE pipe producing line.

The motor for single screw extruding machine is very important because it will work for 24hours every day because you can find the HDPE pipe machine plant will use DC motor on the old extruder.

There is a problem with DC motor, as we need to change its carbon brush after few months running, it will bring more works for us.

With the updated technology, many plastic pipe machine factories will choose AC motor, and firstly we only suggest use Siemens Ac motor.

Figure 11 Siemens Ac motor

The second part is the gearbox:

Gearbox will guomao and change brand for single screw plastic extruder, guomao gearbox will be used in normal speed HDPE pipe extrusion machine and change brand will be used in high-speed PE pipe making the machine.

The third part is the electrical cabinet:

We need to know what electrical device to be used in the electrical cabinet as if there are small troubles on the electrical parts, it is difficult for you to change or buy the same size electric equipment’s.

So, we must choose the top brand in the world. I will show one list to you, when you compare with another factory, you can know which one is better.

I am sure you have a little acknowledge on the extruder, when you check the offers from the pipe machine supplier, first to check these tips, it will show to the factory that you are professional on the plastic pipe machines.

I cannot make sure that you can buy the best price of HDPE pipe extrusion machine from China, but I can sure you will find the best used and best quality pipe machine from China.

Chapter 5: What is HDPE pipe extrusion machine consist of?

In this chapter, we will show you what machines you need to buy when you want to start up your HDPE pipe plant.

HDPE pipe making machine:

You can find the below HDPE pipe processing chart or layout as following, then you can understand what part or machines in the whole plastic pipe production line.

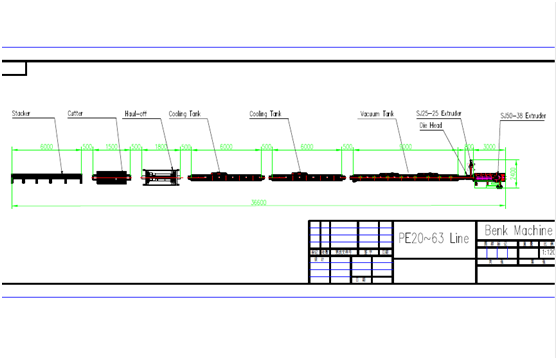

Figure 12 Processing chart for HDPE pipe line

- Single screw extruder

As we have mentioned it is the main parts for HDPE pipe extruding machine, for different sizes pipe, we need different size extruder, you can ask the manufacturer which type of single screw extrusion machine is suitable for you.

The size of an extruder is also chosen by the capacity requirement from you.

It is used to melt HDPE raw material and plasticize the HDPE in screw and barrel.

So how to melt the HDPE raw material?

There is heater on the barrel, it will heat the screw and barrel with the set temperature, for HDPE material, the temperature cannot more than 160, then we will test and check which temperature is the best suitable for our material.

Figure 13 Single screw extruder

We also use Gravimetric control system in our extruder, it is used to control the weight/meter for feeding into the screw, it can control the pipe thickness evenly.

Figure 14 Gravimetric control system

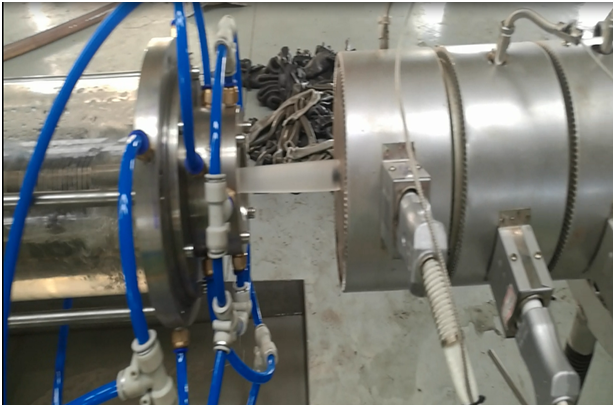

- Plastic pipe extrusion dies

It is made by 40CR, the die head is heated by the heater inside of the mold, we use the temperature sensor to check its temperature, and the mold can be discharged by the screw when we need to clean the mold.

The inner side of the mold is galvanized, the zinc layer will be fray off, we need to take the bush and pin to take zinc again after 2-3 years.

The most important is that we cannot use hard tool to touch with the inner layer, it will damage the mold, we should use the cooper tools to take material out of the mold.

Figure 15 HDPE pipe extrusion die

- Co-extruder

Co-extruder is used to mark the line one the extruder, we can make one or two or 4 lines on the pipes, normally client need one line on the HDPE pipe.

The SJ25/25 and SJ30/25 are most to be used in HDPE pipe making the machine.

Figure 16 co-extruder

- Vacuum tank

We have six meters and 9 meters long, there are two compartments in the vacuum tank.

Each compartment is installed one vacuum pump and water pump, the size of water and the vacuum pump is determined by the size of pipe and tank.

We will install the filter to fill the dirty in the water, then it can extend the service life of the water pump.

The body material of vacuum tank is stainless steel, and we have rich experience staff to weld them the seam, to keep no water leakage.

Sometime maybe you will feel that there is no power in your water pump, as the spray is very small, so you need to discharge the water pump and pull the dirt in the pump. The dirty goods already block the road of water.

Figure 17 Vacuum tank for HDPE pipe extrusion machine

Figure 17 Vacuum tank for HDPE pipe extrusion machine

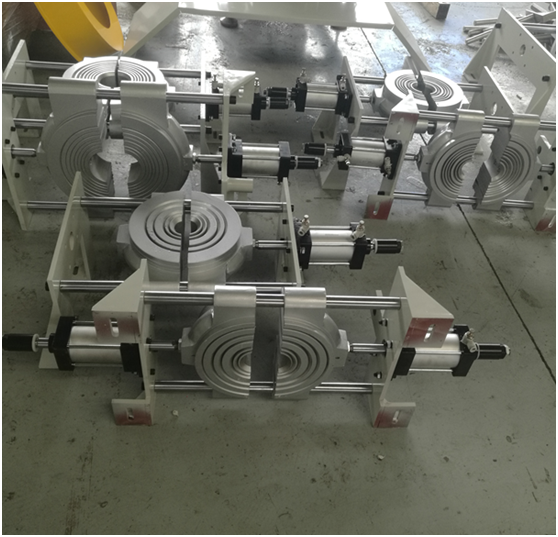

- Tractor

A tractor is used to pull the pipe from the extruder, which speeds up the pipe production, and can make HDPE pipe be straight.

From 20-63mm, we use the belt claw in the haul-off, above 63mm, we use the rubber block on claw in the haul-off.

Figure 18 Belt type Haul-off

The haul-off is controlled by ABB inverter, and we can install normal motor or servo motor on the haul-off.

For above 63mm HDPE pipe machine, we will use rubber block type Haul-off.

Figure 19 Rubber block type Haul-off

Except the claw material is different, we also have the different level motor to be used in the tractor.

The servo motor haul-off is more expensive, but it is more stable when pulling the pipes.

We have two claws haul-off, three claws, four claws, six claws, 8 claws, 10 claws, 12 claws, it depends which sizes of HDPE pipe you want to make.

The claws are controlled by the motor, in the two claws haul-off, it is controlled by the cylinders.

- Cutter

We always chip free cutter for HDPE pipes, the pipe will be compacted by the huff block.

Figure 20 Huff block for compact HDPE pipe

And the huff block is controlled by the cylinder, that is why we need the air compressor in the HDPE pipe production line.

Each HDPE pipe size needs one set huff block, and its material is aluminum.

The blade of the cutter is alloy steel, it can cut the mouth of pipe very smoothly.

We use the Mitsubishi PLC and touch screen to control the chip free cutter, it can make the cutting machine working stable and with less noise.

And we can set the waiting time and cutting length for each pipe on the touch screen.

Figure 21 HDPE pipe cutter

Figure 21 HDPE pipe cutter

7. Stacking Rocker

There are two type design for the stocking frame now, one is used for smaller pipe, and other is used for bigger size PE pipes. For small pipes, some client also will choose winder to work with stacking frame, as maybe your client need coil pipe in his market, and some client need straight pipes.

Figure 22 Stacker

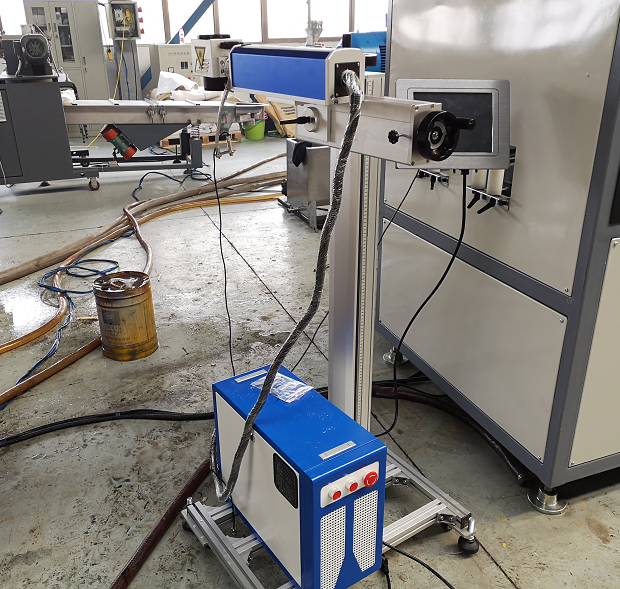

8. Laser printer machine

It is very famous to be used in the plastic pipe production line recently, before it is ribbon printer, as it is not good, and ribbon will be waste a lot, now many clients would like to choose laser printer.

Figure 23 Laser printer

What you need to do in your factory?

Electronic- power supply

When you apply the power, you should check with the pipe machine factory how many the total installation power for all machines?

Then you can go to apply the transformer in your country.

Water

You can use water chiller or water tower in your plant if you plan to have more production, it is better to use the water tower.

And we need to use the water pump to suck the water from pool to our vacuum tank.

Air-compressor:

It is necessary for the plastic pipe extruding machine, as our machine always need air in the cylinder if you already have the air compressor in your factory, then you do not buy a new one.

If you do not have, you can check with the pipe machine manufacturer, they will guide you to buy the air compressor according to the demands in the HDPE pipe production line.

After you have above ideas or information, you will know how much cost the HDPE pipe plant will be charged you.

If you want to know the project report for HDPE pipe plant, please contact our sales or engineer to assist you to finish it.

The HDPE pipe manufacturing plant project report will have the process PDF file, specifications of the HDPE pipe manufacturing machine, regularly maintain the way for HDPE pipe machines, how much cost for raw material and so on.

Chapter 6: What is the application of HDPE pipe

Here, we will talk about PE80 or PE100 solid pipe, so the following applications are based on these two PE pipes.

1. Water-supply system

HDPE pipes are can be used water supply pipe in the city, village, home or factory, the water is normal water, HDPE pipe cannot be used for hot water.

2. Irrigation system

PE pipe can be used as irrigation pipe in farm, garden

3. Water treatment system

HDPE pipe can be used in the city water treatment system.

After we know the HDPE pipe can be used in the above fields, all are in the water supply system, when we use the HDPE in the system, what is it advantages and disadvantages?

Advantage:

1. Easy to match the welding and electrofusion welding to form a closed anti-seepage system. When laying along the groove, the amount of earthwork for trench excavation can be reduced and the number of accessories can be reduced.

2. Lightweight and easy to install and handle;

3. Strong wear resistance and excellent hydraulic performance, without the outer layer protection in the buried pipeline. It can be applied to earthquake and mining area settlements and can also be laid at the bottom of rivers by sinking method.

4. Chemical corrosion resistance, resistance to internal, external and microbial corrosion, corrosion resistance, and health. It is suitable for transporting acidic and alkaline substances and transporting sewage, natural gas, gas, and other substances;

5. Good environmental adaptability and frost resistance and can be used for indoor and outdoor water supply pipes.

6. long service life, with a service life of more than 50 years;

7. Easy to recycle.

Disadvantages:

1. Matters needing attention in the application of HDPE water supply pipelines

2. It should be used as a sheltering measure when it is laid out in the open air and there is sunlight.

3. Buried HDPE water supply pipeline, DN≤110 pipeline installation in the summer can be slightly serpentine laying, DN≥110 pipeline because of sufficient soil resistance, can resist thermal stress, no need to reserve pipe length; winter, no need Reserve the length of the pipe.

4. When the HDPE pipeline is installed, if the operation space is too small (such as pipeline wells, construction inside the ceiling, etc.), the fused connection method should be adopted.

Conclusion: HDPE pipe is used in a water supply system in our life.

Ø Chapter 7: How to install HDPE pipe and connect HDPE pipes?

In the last chapter, we have talked the uses of HDPE pipes, when we use the HDPE pipe, how we connect them, as we know we cannot make the HDPE pipe very long when we produce the PE pipe, otherwise, it will not easy for us to transport them.

Normally, we can see 3 meters, 4 meters, 6 meters max. 12 meters length HDPE pipes in the market.

How we connect them when we use them?

1. HDPE pipe fitting

You can find HDPE pipe fittings, they HDPE tee, HDPE pipe reducer, pipe upper, HDPE U fitting, HDPE y pipe fitting, they are made by plastic injection machines.

You just need to insert HDPE pipe into the HDPE pipe fitting with glue. Normally, the pipe fitting is used small project or house use.

PE pipe fitting

2. PE hot-melt machine

PE hot-melt machine is widely used in big size pipe connection or construction project.

We will use miller to mill the mouth of two pipes and make them smooth.

Then we will use the hater in the heat-welding machine to heat two mouths of pipes.

After milling, we will check whether two pipes are in the same level by our eyes, if they are in the same level, we will put the heater in the middle of two mouths of pipes.

When the temperature up to 220 c, we will remove the heater, then press the push button, two pipes will be pushed together by the cylinders in the machine.

We can remove the cylinders after pipe cooling down.

HDPE pipe heat-melt welder

It is very easy to install the HDPE pipes, if you want to buy the heat-melt welder, please contact our sales for contact information.

Conclusion: Benk machine is not professional on making HDPE pipe extrusion machine, we also can assist you to buy the upstream and downstream machine or products with high and qualified quality.

Chapter 8: How to solve the troubles in the HDPE pipe producing machine?

Firstly, let us know what troubles will be happened when we produce HDPE pipes.

1. The HDPE pipe is not round

First step: When the HDPE is not round, you can check the mold pin and push, normally we will adjust the push to make the thickness even.

Second step: Please check your vacuum pump in your vacuum tank, if the effect of the vacuum pump is not enough or not good, you need to change the vacuum pump.

Third step: Please check when the HDPE pipe is still hot or normal temperature when HDPE come from your vacuum tank, if still hot, your cooling system is not enough.

Fourth step: Please adjust smaller of your air pressure in the haul-off, if pressure is too big it will change the roundness of HDPE pipes.

2. The surface of HDPE pipes is not shinning

Step 1: please check your HPDE raw material is dry or not, you can use the dryer to dry the PE pellets before feeding them in the two single screw extruder,

Step 2: When the pipe is still the same, you can slow the extrusion speed in your single screw extruder.

The cut mouth of HDPE is not neat

Please check the huff blocks are on the same level in the cutter, you can use the level measurement to check them, and there are buttons to be adjusted the huff blocks.

After checking, then please check the cutting blade, make sure the cutter blade is vertical and feeding speed is stable, you can check the pressure on the cylinder in the cutter.

3. Electrical equipment damaged

With a long time working, the contactor maybe will be burned by unstable electric current, it is very easy for us to know which zone or which one contractor is broken.

Normally, we will check this zone is working or not, if not working, we will change the new one contractor to try again.

So, when you buy the HDPE pipe extrusion machine, it is better to buy the spare parts with the machine, like temperature controller, thermocouple, contactor, switch, button, cutting blade, heater…

Conclusion, some troubles on the machine is very accidental, we cannot estimate all troubles, but we can prevent or reduce the possible troubles on you when we make the machines.

Like, we use the high-quality electric wire, high-quality electric device, and we use the universal guaranteed ABB inverter, and you can get after-sales service in your country when there are troubles on the inverter.

If your troubles still not on the above list, please tell our engineers your troubles, we can assist you to solve them quickly and free.