PP Hollow Construction Formwork Extrusion Line

| Extruder | SJ120/35 single screw extruder |

| Mold | Hollow board die(15-18mm) |

| Forming machine | Three sets vacuum and forming module |

| Dimensions of PP hollow board line | 30x2x3meters |

| Total power | 210Kw |

| Width of mould | Minimum 1000mm |

| Delivery time | 50 working days |

| Guarantee | 1 year |

| Voltage | 220V, 380V, 415V, 440V |

| Production capcity | 400-600kg/h |

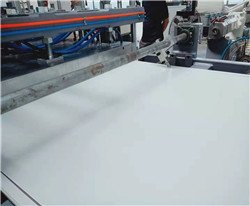

Your first choose for PP hollow construction formwork extrusion line

PP hollow construction formwork extrusion line also named PP hollow construction board extrusion machine, it is used to make 15-18mm thickness construction template.

PP hollow construction formwork extrusion line can make two size PP hollow construction board, which are 1220x2440mm and 915x1830mm, the construction formwork can be used to replace wood formwork or iron formwork.

The benefit for the PP hollow construction template is lighter than wood and iron. Also it is environment friendly to our nature. We can use recycled or new PP raw material to make the construction board, and the construction board can be recycled to make PP construction board again.

Our PP construction board extruding machine can make single or three layer PP hollow construction board, when we make three layers PP construction board, you can save cost on the raw material.

Benk PP hollow construction formwork extrusion line has high capacity which can reach 400-600kg/h, it is full automatic production line, we also need to upload the PP raw material, and discharge the finished PP hollow construction board. It is easy to operate our PP hollow construction board machine.

Benk PP hollow construction board machine is used for 24hours running, the whole machine including single screw extruder, gear pump, mould, vacuum calibration table, side saw, haul-off, second haul-off, cutter, stacker, water chiller and crusher.

- Production images

- Data Sheet

- Testing Video

- Send Enquiry

Data of PP Hollow Construction Formwork Extrusion Line:

|

NO. |

Products |

Quantity |

|

1 |

SLG vacuum Loader & SDG hopper dryer |

2sets |

|

2 |

SJ120/35 Single screw extrude with Siemens PLC and touch screen |

1set |

|

3 |

SJ75/35 Single screw extruder |

1set |

|

4 |

Hydraulic Screen Changing device |

2sets |

|

5 |

Separator (A/B/A layer) |

1set |

|

6 |

Mould (T-die material P20) |

1set |

|

7 |

Vacuum Calibration machine |

1set |

|

8 |

Five roller Haul off |

1set |

|

9 |

Cooling bracket |

1set |

|

10 |

Second Haul off |

1set |

|

11 |

Cutter |

1set |

|

12 |

Stacker |

1set |

PP hollow construction formwork extrusion line: The Ultimate Importers Guide

This is the ultimate guide to importing the PP hollow construction formwork extrusion line from China. Stick around to learn:

- The work of a PP construction-hollow production machine

- Its main parts

- General importing tips

- How to choose a credible Chinese Supplier

- PP hollow construction formwork uses and advantages

- And more!

You’ll love this importation guide that’s brought to you by Benk Machinery’s professional team. And we hope you’ll get all the necessary information so as to make an informed purchase decision.

Let’s get started:

![]()

PP hollow construction board extrusion line

Chapter 1: Parts of PP Hollow Construction Formwork Extrusion Line

In this first chapter —I’ll introduce you to the components that comprise the PP hollow construction formwork extrusion line.

You’ll also learn the function and how each individual part works. So, firstly:

1.1. What does the plastic formwork production line do?

The PP formwork production line continuously produces a uniform and continuous PP hollow formwork template. At the end of the line, the board is cut into separate length-wise pieces.

![]()

PP Construction formwork templates

And how does it accomplish this function:

Put as simply as possible:

Solid PP resin raw material is melted into a malleable molten polymer. Then, forced through a shaping die and in the process it adopts the desired shape. The formed profile is cooled and solidifies.

What is the final shape of the PP Hollow Construction formwork template?

PP hollow construction formwork boards have three layers of PP grid sheets. You can see that it’s called a hollow board because of the presence of square holes forming a grid layout.

![]()

A cross-sectional structure of PP Hollow formwork templates

Main Use:

Labeled as energy-saving and green environmental product, plastic construction formwork boards are mainly utilized in the construction industry as templates (also called formwork or shuttering).

![]()

Plastic formwork for concrete construction

Formwork is basically a temporary mould into which concrete is poured and allowed to dry & form. After which, the formwork material is removed.

You’ll be glad to know that PP hollow formwork boards are being preferred over wood, composite steel, bamboo, and all-steel formwork.

Dimensions

PP hollow grid formwork sheets usually have a thickness of 12mm to 18mm.

There are produced as rectangular boards with popular dimensions being 2440×1220 or 1830×915mm. However, you can customize the dimensions based on the client’s specifications.

Since their main use is during construction, they don’t have elaborate decorations or colors. Common colors are gray or black.

PP hollow construction boards raw material

You need raw materials that will be converted into the final products. Polypropylene (PP) is the main raw material in this process.

Using our machine you can use 100% recycled PP granules, or PP virgin resin. You can also include a high percentage of fillers to reduce the cost of manufacturing.

And what is PP?

It is a thermoplastic such as PE or PVC. In effect, it’s recyclable.

You can buy PP raw material in powder or granular form. The powder is white. The granules can be milky white. Virgin granules are somehow translucent. Recycled PP granules are black, blue or even yellow.

And why is PP used to make construction formwork boards?

It has several favorable properties including excellent chemical stability against acids, alkalis, and organic solvents. It also has good mechanical properties, odorless and good heat resistance.

We’ll dive more into PP plastic formwork and its advantages in chapter 4. But next, I want to introduce you to the PP hollow board formwork extrusion line:

|

PP Hollow Formwork Templates Weight Table |

||

|

W x L |

Thickness |

Weight |

|

915mmx1830mm |

14mm |

10kg |

|

915mmx1830mm |

15mm |

12kg |

|

915mmx1830mm |

18mm |

13kg |

|

1220mmx2440mm |

14mm |

18kg |

|

1220mmx2440mm |

15mm |

20kg |

|

1220mmx2440mm |

18mm |

25kg |

In the table above, you can see the total weight of the final boards based on their thickness and dimensions.

1.2. Parts of the Building PP Hollow Sheet Extruder Machine

The PP formwork extrusion line consists of the following main parts:

- Single screw extruder – (Mostly two for co-extrusion)

- Mould (die head + vacuum calibration table)

- First haul-off machine (six rollers)

- Cooling bracket/table

- Second haul-off (two rollers)

- Edge trimming device

- Horizontal cutting machine

- Stacking table

All these parts work together to produce complete PP formwork templates. So next, let’s look at the production process step by step:

1.2.1 Feeding of raw materials (Auto feeding machine)

Raw materials usually have to be mixed together before they enter the production line. Some companies buy premixed compositions in the form of granules. Others prefer to prepare their own compositions.

Benk will help you choose the most suitable material preparation option. Once the materials are ready, they are fed into the line by an automatic feeder.

So, what is an auto feeder?

![]()

Auto feeder machine showing motor, control panel, material hopper, and feeding tube

It’s a type of screw conveyor. Its main parts include a material tank, inclined feeding tube, and motor.

Working principle:

- PP raw materials are fed into the material hopper.

- The hopper’s walls are inclined to allow the free flow of materials into the feeding tube’s opening at the bottom.

- The rotating helical screw driven by an electric motor takes up the materials and conveys them upwards.

- At the end of the feeding tube, materials are deposited inside a hopper. Some hoppers called dry hoppers can be used where the material has a high moisture content and requires further drying.

Our DTC screw feeder models ensure continuous automatic feeding of raw materials. And will save you labor costs by eliminating manual bucket feeding used in some factories.

Let’s move on to the next process:

1.2.2 Extrusion (Extruder)

The goal of the extrusion process is to convert solid resin raw material into a homogeneous well-mixed polymer melt. The melt is then shaped inside the extrusion die that’s connected to the extruder. And then set inside a vacuum calibration mould.

What is an extruder?

![]()

Our high-quality PP hollow construction template extruder

It’s the equipment used for the extrusion process. It consists of the following parts:

- Drive system— The motor, gearbox, and thrust bearing. There are two types of drives—direct and indirect.

- Feed system— The feed hopper, screw feed section, and feed throat.

- Heating system—Consists of heaters located along the barrel. Heaters are grouped into zones with one thermocouple controlling each zone.

- Electrical control system—For regulation of the extruder’s components, electricity and other downstream machines.

- Vacuum system—Fitted to remove fumes created as the resin + additives melt inside the extruder.

- Barrel cooling system— Wind fans also mounted on the extruder’s barrel. The system requires very little maintenance, unlike a water cooling system.

- Screw and barrel– Where the raw materials are conveyed, melted, mixed, compressed and pressurized.

When buying an extruder, you’ll find that extruders are classified based on the number of screws. There are single-screw and double-screw extruders.

Extruders are also distinguished based on the L/D ratio (Flighted length of the screw to the nominal diameter).

Generally, extruders with large diameters and those with longer L/D ratios achieve greater output.

Are you new to plastic extrusion manufacturing?

Don’t worry:

Our team will recommend the best extruder model for your PP hollow construction formwork extrusion line.

Co-extrusion

For the PP hollow construction production machine, there are two extruders working together.

You’ll see how this works when we talk about the multi manifold co-extrusion die.

Working principle of the extruder:

- Materials are constantly fed into the feed hopper and maintained at a constant level.

- When the feed-throat is opened, materials freely flow into the extruder’s barrel.

- Ideally, the raw materials should fall to the outside of the screw, so as it turns down it takes up the materials into the barrel easily for conveying.

- Heaters on the barrel supply the heat required to cause the polymer to melt.

- The turning motion of the screw mixes and homogenizes the melting polymer.

- Decreasing channel depth also leads to compression of the melt.

- At the end of the barrel, the screw feeds the homogenized polymer melt into the die.

1.2.3 Moulding process(Die head + Vacuum calibration platform)

Shaping the polymer melt into a preliminary shape occurs as the melt passes through the die head. It then leaves for cooling and calibration in the calibration tooling.

What is an extrusion die head?

![]()

Die head for PP Hollow formwork templates

You can think of the die head as a hollow container that gives the polymer melt its shape. The die head is directly mounted onto the extruder’s barrel via the die adaptor.

In between the extruder and the die, there is a tool called a breaker plate. This is just a round disk with holes. The breaker plate is also used in conjunction with a screen pack (metal mesh used for filtering contaminants from the melt)

Now, we have said that we use two extruders in the PP hollow construction formwork extrusion line.

So how does the die combine these two streams?

![]()

Die head next to the calibration tooling

Well, it has multiple manifolds (flow channels).

The die for producing Plastic Concrete Formwork for Construction is a T-die with a clothes-hanger type flow channel.

Another thing to note is that the die consists of built-in heaters. These are used to maintain the die at the same temperature as the melt.

Obviously, we don’t want the melt to cool and stagnate inside the die. Manifolds for sheets can either adopt a fishtail, coat-hanger or T-slot distribution mechanism. You can learn more here.

Next’s let’s highlight quickly how this die works:

Working principle:

- The primary melt stream enters from the back. The second stream is introduced inside the die from the side.

- The die has multiple manifolds depending on the number of the PP hollow formwork template layers. So two streams are split to make the three-layer structure.

- After the polymer melt is distributed evenly in different manifolds, the streams are combined near the die exit.

- So as melt leaves the die, the melt streams come together to form the co-extruded structure.

Hydraulic screen changer: A Note

![]()

Hydraulic screen changer (hydraulic unit + screen changer) – yellow

During production, the screen pack accumulates contaminants and gets clogged. This results in the reduction of the extruder’s output.

So the screen pack may require constant changing. And this we automate by using a hydraulic screen changer.

What is a vacuum calibration platform?

![]()

Calibration table for the PP Hollow Building production line

It’s also called the vacuum setting die or dry vacuum calibrator sizing tank. And it’s used for calibrating complex shapes requiring a high degree of precision.

And calibration is simply the process of standardizing the PP hollow template’s dimensions. This takes place inside a calibration tooling that’s mounted on a calibrating table or platform.

![]()

Water & vacuum connections on the vacuum calibration platform

The calibrator tooling is also connected to a vacuum system and water circulation cooling system (with water pumps, water reservoir, and heat exchanger).

Let’s see how it works:

Working principle:

![]()

PP hollow formwork board leaving the calibration tooling

- The profile enters the first calibration chamber. There are two chambers with each connected to triangle close-circuit vacuum tubes. It also has channels where cooling water circulates.

- The first calibration tooling smoothens the surface of the hot extrudate as it comes into contact with it.

- Vacuum pumps constantly maintain a partial vacuum inside the tooling. This results in negative pressure causing the wall of the template to be drawn against the calibrator’s inner walls.

- Cooling occurs as the extrudate comes into contact with the cold inner metal surface of the tooling. The water that has absorbed the heat is recirculated and re-chilled by the heat exchanger.

1.2.4 Pulling or traction (5 Roller Haul-off)

![]()

5 Roller Traction for PP Hollow construction formwork production line

Pulling is key in the extrusion process. And it’s done after the extrudate flows out of the die head.

The pulling force should be constant and even. This is because it has a direct bearing on the shape of the product, the orientation of the molecules, and hence the physical properties of the PP Hollow formwork templates.

You might wonder:

What will happen if pulling is uneven?

Pull the extrudate too slowly and the PP hollow formwork construction template might deform. Vice-versa, draw it too rapidly, and the PP hollow formwork template will stretch.

The right speed matches the extruder’s throughput and extrudate’s die exit rate. The overall line speed is usually 2 meters per minute.

What is a haul-off machine?

![]()

First traction machine for PP hollow construction extrusion machine

Also called the traction machine, it provides the pulling force.

There are two pulling operations in the PP construction board manufacturing process. The first puller consists of up to five or six pairs of rollers.

Its role is to draw the plate from the calibration table evenly.

Working principle:

- A motor continually drives the rollers.

- The gap between the upper and lower rollers is slightly less than the template’s thickness. This promotes more grip on the extrudate ensuring little chance of slippage.

- The pulling speeds are automatically adjusted by the PLC control based on the line speed.

1.2.5 Cooling (Cooling bracket)

![]()

Cooling bracket for PP Hollow construction line

There are two mechanisms used to cool plastic extrudate: water or air cooling. For the PP hollow construction formwork production line, the dry vacuum calibrator ensures the extrudate has cooled enough removing the need for cooling by immersing the board in chilled water.

Instead after leaving the calibrator, it’s passed over cooling brackets.

What is a cooling bracket?

It’s a flat conveying platform consisting of evenly spaced galvanized metal rollers.

1.2.5 Second haul-off (2 roller puller machine)

![]()

Second traction machine for PP hollow formwork extrusion line

The second traction machine consists of just two pair of pulling rollers. Its role is to remove stress from the extruded PP formwork template.

1.2.6 Cutting (Longitudinal trimming + Horizontal cutting machine)

There are two cutting processes carried out in the production of PP hollow formwork boards. First, longitudinal trimming of excess materials from the edges of the board.

Next, we have the accurate length-fixed cutting of the extrudate into pieces.

What is a longitudinal cutter?

![]()

Longitudinal cutting device mounted after the calibration machine

The longitudinal cutter is a fairly simple tool. There usually two double blades mounted either after the calibrator or after the first haul-off unit.

![]()

Longitudinal cutting in progress

The profile must not have hardened completely to make splitting difficult.

What is a horizontal cutting machine?

![]()

Longitudinal cutting machine

Also called the cutter, it’s positioned after the second haul-off rollers. Due to the thickness of the PP hollow formwork template, a metal saw is used for cutting.

Working principle:

- The PP hollow formwork template is drawn into the cutter by the haul-off machines.

![]()

PP hollow template pushed into the cutter

- Once the sufficient length has passed through, the cutter receives the cutting signal. It will clamp down on the template before activating the saw.

- Devices used to determine if the desired length has passed through include timers, PLC controls or limit switches

![]()

Control panel for horizontal cutting machine

- The cutting saw is moved through the board until it performs a clean cut. The saw comes with a lockout to stop it when the E-stop button is pressed.

- Saws also have carbide tips that prevent overheating. Remember the board’s edges will melt if high temperatures are generated during cutting.

- After cutting, the clamps are lifted, and the cut piece pushed into the stacking table by the incoming profile.

1.2.7 Stacking (Stacking/collection table)

![]()

Stacking platform for PP hollow construction template extrusion line

The collection table holds the cut and finished PP hollow formwork construction board. Subsequently, they are removed and stacked by the workers. The collection table is sometimes fitted with a tilting mechanism for automatic take-off, but it’s not as necessary for this line.

![]()

Side-view of our high-quality stacking table

1.3 Auxiliary machines

Some auxiliary machines that you may need include:

- Plastic Crusher

- Plastic Pulverizer

- Mixers

- Air compressors

- Dust-suction device

![]()

Our hot selling plastic crusher machine

![]()

Industrial Chiller machine

We’ll recommend the auxiliary machines you may need once you make your inquiry here.

Chapter 2: Advantages of our PP Hollow Construction Template Board Extrusion Line

- Simple and linear structure

This makes our PP hollow construction template extrusion line easy to install. And the line takes up a small space inside your warehouse, allowing you to easily add more lines.

![]()

PP hollow construction board extrusion line on the workshop floor

- Adopts advanced world–famous brand parts

With our well-established supply lines with top manufacturers, we use pneumatic, electric parts and operation parts from world-famous brands like ABB, Siemens, Omron, and Schneider Electric.

- High automation

We can achieve a high degree of automation by employing PLC controllers to interface between different production equipment. The PLC control runs the extruder regulating the feeder settings, screw speeds, etc. It also synchronizes the pulling speeds, the cutter movement, etc. This keeps the product quality consistent.

- Adjustable upper and lower mold lips

With a sensitive die lip adjustment via the push bolt, you can easily control the die orifice. This makes it easy to control the product’s thickness and control any errors within a 3% range.

- Well-made vacuum calibrator

We use specially treated materials for the construction of the dry vacuum calibration tank. This promotes maximum wear resistance and extends the component’s life. Its surface is also highly polished and non-sticky. It’s also fully adjustable allowing it to be precisely aligned with the extrusion die and other downstream equipment.

- High-quality extruder

Our PP hollow construction board extruders have stood the test of time. They adopt special screw systems based on the nature of the raw materials. Fitted with sensors and intelligent temperature controllers, they give back precise process data. They also have good extruding performance and plasticization effect.

- Excellent co-extrusion die design

Our multi-manifold co-extrusion die incorporates special CrNiMo steel alloy. Its die lips are precisely polished, and surface galvanized by chrome treatment for long life.

- High-torque and stable traction machines

Our traction machines, excellent at low-speed pulling. Their speeds are accurately synchronized to prevent slippage. And the traction rollers are anti-aging with good flexibility and elasticity.

Chapter 3: Import Tips for the PP Construction-Hollow Production Machine

![]()

Plastic concrete formwork panels used to make cross-walls

3.1. PP Hollow Construction Formwork Extrusion Line Price

Do you want the best & lowest price?

You may wonder:

How can Benk offer low prices without compromising the quality?

It’s because we make each line at our own workshop. We don’t subcontract or trade lines from other manufacturers. You’ll be dealing directly with us.

3.2 Things to Consider to Find a Good Manufacturer

Here are some general pointers that will allow you to partner with a reputable PP hollow construction formwork supplier:

- Call the supplier. Once you find their contact information on their website, place the call. You’ll establish if the supplier has provided credible contact information. And you’ll have the chance to speak directly with company’s representative.

- Check the supplier’s online presence. Do they have a website, and is it updated? Are there are signs that the company participates in trade shows or other industry events. Do they publish helpful content for new buyers?

- You can ask for the supplier’s business license and company registration number for verification.

- Ascertain that the supplier’s products conform to different quality certifications. For instance, ISO, CE and SGS standards.

- Ask for references and to speak to previous customers the company has sold production lines to.

- Conduct a factory visit and inspection either in person or by hiring an inspecting firm before your order.

- Ensure that the PP hollow construction formwork line is fully tested before shipment.

- Conduct proper due diligence before making transactions. Contracts should be also property signed, chopped, and legally binding.

- Find a supplier willing to create a trustworthy and long-term relationship. They should have no problem providing extra information and clarifying on issues as requested.

- Check to see if the company also offers installation support and technical assistance long after you buy the PP construction-hollow production line.

3.3. Packaging and delivery of PP Hollow Construction Formwork Extrusion Line

You might be wondering how the line is shipped, delivered or packed?

For shipping, it depends on the agreed pricing and shipping terms. Some pricing terms include FOB, CIF, CNF or EXW.

For packing, parts are packaged in wooden pallets. If the wood pallets are destined for European countries, they’ll be fumigated.

The components will then be loaded into containers. We can wrap parts with PE film for further protection.

Benk takes special care to ensure the components reach in good condition. And we can pack the products based on your special request.

![]()

Parts of the PP hollow construction extrusion line assembled for testing before shipment.

3.4. Some reasons to work with us

- For over 10 years, we have been supplying plastic extrusion and recycling machinery internationally.

- Well-versed and experienced team with each of our team members having over 10 years experience in their respective fields.

- We can provide turnkey solutions and customize the PP hollow shuttering board extrusion line to your exact specification.

- Get factory layout and other technical diagrams to set up your factory successfully.

- We can send an engineer to help you during the installation. The engineer can also train your first-line operators until they can run the PP hollow construction formwork extrusion line independently.

- One year guarantee.

- ISO, CE, and SGS inspected machines.

- Best possible price.

- Free consultation and guidance on choosing the most suitable parts for your line such as the extruder’s model and other auxiliary machines.

- Free formula support for PP Hollow construction templates.

- Thorough testing of machines for several hours in production mode before shipment.

Chapter 4: Why are PP Hollow Sheets Desirable as Construction Formwork

![]()

Formwork for concreting

In this chapter, we’ll examine:

- The different uses of PP hollow formwork templates..

- Advantages of using plastic formwork material.

- Disadvantages of conventional formwork materials.

Straightaway, let’s talk about the other names of PP hollow formwork boards. They are also called:

– PP construction formwork template

– PP hollow template recycled plastic building boards

– PP hollow grid construction boards

– PP hollow shuttering boards

– PP hollow building template

– PP construction templates

– PP concrete column molds

4.1. PP hollow building formwork template—Definition

So what is formwork?

It’s a temporary molding structure. The freshly mixed concrete is poured inside the mould during construction. It’s then compacted and left to set.

It takes 24 hours to 48 hours for the setting, and afterward the concrete is cured.

The formwork is usually removed immediately after setting. But when constructing an upper floor in a storied building, the formwork will be removed after the curing process, which may be after 28 days.

What is the most popular type of formwork?

Around the world, wood formwork is the most used. Not because of its merits but it’s easily available. And many people have experience using it.

So what properties must a formwork material possess?

– Strong enough to bear live or dead loads

– Water-resistant—since concrete includes water

– Capable of being propped and braced either horizontally in case of creating levels or vertically when making walls

– Easily removable with no damage to the concrete

– Must form tight joints that prevent any leakage of wet concrete

– Easy to combine with other materials

– Should promote safety

– Lightweight and portable

4.2. PP construction formwork uses

PP construction formwork templates are used in diverse environments. You’ll find them used in coastal areas, underground works, mines, seawalls, dams, etc.

Here is a list of their common uses:

– Construction Engineering e.g. high rise buildings

– Bridge-Tunnel Engineering

– Water Conservancy

– Hydropower Engineering

– Mine dikes

4.3. Advantages of PP Hollow Sheets

1) Good range of mechanical properties—Light-weight, wear resistance, don’t expand or shrink, fire retardant, high impact resistance, high-strength, and good tenacity.

2) Smooth surface—That’s easy to clean and upon concreting it gives an excellent forming effect

3) Waterproof—PP hollow construction formwork boards don’t absorb moisture. This makes them suited for damp and underground applications.

4) Acid and alkali resistant—The boards are corrosion resistant and require no preservative treatment during storage.

5) Long reusable life—PP formwork has a reusable rate of up to 60 times. This alone makes it more economical than wood or bamboo formwork, which may appear relatively cheaper at first.

6) Recycled and reprocessed—Damaged PP hollow formwork can be recycled. And the recycling process is not complicated. The damage boards are crushed into small pieces and reprocessed into raw material granules or new plastic products. Not only does this save resources, but it also ensures the boards meet the requirements of the green industry.

7) Boost construction efficiency—PP hollow formwork boards are light making them easy to carry and use. They are also reliable and require less labor power. Customers will save time and costs by using them.

8) Easy to remove –After the concrete has set, there is no need for oil or any brushing release agent during the removal process. Concrete doesn’t stick to the surface of the plastic formwork templates. The ease of removing them also promotes efficiency and safety.

9) Good processability- It’s possible to saw, drill and nail the PP hollow construction form templates.

10) Withstands high temperatures—Most formwork is exposed to direct sunlight and used in high temperate climates. Luckily, PP construction boards can handle high temperatures well and will remain smooth and stable in hot conditions.

11) You can combine them with bamboo, plywood and steel frames easily.

12) The templates are simple to clean.

13) It’s also possible to create different impressions on the surface of the boards if there need be.

4.4. Limitations of PP Hollow Formwork alternatives (Wood, Steel & Bamboo)

Several other materials are used as formwork including aluminum, steel, fabric form, timber, plywood, etc. Each material has its merits and demerits.

Adoption of PP hollow construction templates in the construction industry will continue to grow, as they are not prone to limitations facing the conventional formwork materials.

Bamboo

![]()

Bamboo used in construction for making scaffolding

– Poor resistance to fungi and bacteria

– Sensitive to attack from insect

– Requires preservation

– Durability problems

– May shrink when they lose water

Timber

![]()

Timber formwork used for making concrete columns

– Absorbs water and may rot during storage

– Promotes wastage of forest resources

– Time-consuming to since it’s fabricated on site

– Labor intensive

– Grout may leak between joints formed by timber planks especially after they shrink

– Limited reuse

Steel

– Available in limited sizes and shapes

– Takes more time and energy to produce

– Difficult to nail

– Expensive

– Corrosion occurs after long periods of use

– Can be cumbersome and difficult to handle

Contact us Today!

Start your importation journey with Benk Machinery today. Our technical team is on standby ready to guide you along the way. We’re very keen on providing you with a high-quality PP hollow construction board extrusion line. That will bring you profits for many years to come.

Contact person: Tony Cao.

Email: [email protected]

Phone: (+86) 13052271776

WhatsApp/WeChat: Whatsapp:+86-13052271776

You can also send us a message via our live chat. Welcome and we’re looking forward to a fruitful collaboration.

Frequently Asked Questions

- Are you a trading company or manufacturer?

Benk Machinery is a plastic equipment manufacturing company.

- How long is your delivery time?

Generally, the plastic formwork production lines are ready for shipment within 30-60 days. But it can be faster, if we have the line in stock. The lead time also depends if you need a turnkey project.

Q3: How soon can I get the quotation?

Just send us a message requesting more information on the Building PP Hollow Sheet Extruder Machine. You can also supply pictures of the type of PP hollow construction formwork templates you wish to manufacture. Also, you can specify the type of raw materials you’ll be using. We’ll do our best to send the quotation in less than 24 hours.

Q4: Can you provide technical assistance to us?

Yes. Our technical team also offers plastic extrusion support to our past clients. We can offer online video support or even arrange for a technician to travel to your factory.

Q5: What is the payment term?

We can offer T/T, L/C, among other terms.

Q6: Can I visit your factory?

Yes. Arrange a visit by contacting our support team. We’re located at 300m West of Luyuan Over Pass Bridge, Zhangjiagang, Suzhou, Jiangsu, China (Mainland).

Other Related Lines

WPC/PVC foam board extrusion production line

PVC imitation marble extrusion production line

PVC ceiling panel profile extrusion production line